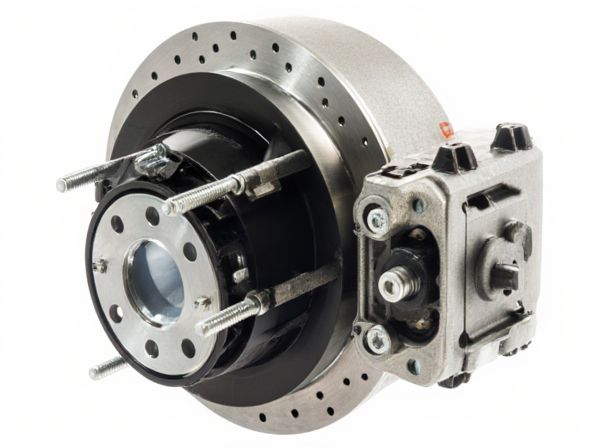

Photo illustration: Hydroboost Systems vs Vacuum Boost Systems

Hydroboost systems use hydraulic pressure from the power steering pump to provide braking assistance, offering more consistent and reliable performance compared to vacuum boost systems. Vacuum boost systems rely on engine vacuum to amplify brake pedal force, which can be less effective during low engine vacuum conditions such as heavy acceleration or turbocharged engines. You should choose hydroboost if you need stronger braking power and improved performance in demanding driving situations.

Table of Comparison

| Feature | Hydroboost System | Vacuum Boost System |

|---|---|---|

| Power Source | Hydraulic pressure from power steering pump | Engine vacuum |

| Brake Assist Type | Hydraulic boost | Vacuum boost |

| Performance | Consistent high boost, ideal for heavy vehicles | Effective at low to moderate boost levels |

| Application | Trucks, SUVs, and vehicles with low engine vacuum | Most passenger cars and light vehicles |

| Reliability | Less susceptible to vacuum loss issues | Dependent on engine vacuum; reduced performance if vacuum drops |

| Cost | Higher initial cost and complexity | Lower cost and simpler design |

| Maintenance | Requires hydraulic system checks | Minimal maintenance |

| Brake Feel | Firm and consistent pedal response | Softer pedal feel under certain conditions |

Introduction to Brake Booster Systems

Hydroboost systems utilize hydraulic pressure from the power steering pump to enhance braking force, providing consistent performance regardless of engine vacuum levels. Vacuum boost systems rely on engine manifold vacuum to amplify brake pedal force, which may diminish under heavy engine load or turbocharged conditions. Understanding these distinctions is essential for selecting the appropriate brake booster system tailored to vehicle specifications and driving demands.

How Hydroboost Systems Work

Hydroboost systems use hydraulic pressure from the power steering pump to assist brake pedal force, providing consistent and strong braking performance. This system operates by transmitting pressurized fluid to a piston in the brake booster, enhancing the driver's input without relying on engine vacuum. Hydroboost systems are especially effective in vehicles with low vacuum availability or diesel engines, offering improved reliability under heavy-duty conditions.

How Vacuum Boost Systems Work

Vacuum boost systems operate by utilizing engine vacuum pressure to amplify braking force, drawing atmospheric pressure into the brake booster to assist the driver's pedal effort. When the brake pedal is pressed, atmospheric air enters the booster chamber, creating a pressure differential against the vacuum side, which multiplies the force applied to the master cylinder. This system is commonly used in gasoline engines where intake manifold vacuum is readily available to deliver efficient and responsive power braking.

Key Components of Hydroboost and Vacuum Boost

Hydroboost systems rely on a hydraulic pump powered by the power steering system to provide braking assistance, featuring key components such as the hydraulic booster, master cylinder, and pressure lines. Vacuum boost systems use engine vacuum generated by the intake manifold, incorporating a vacuum booster, check valve, and vacuum hose as their primary components. The hydraulic approach offers consistent brake performance under high engine load, while vacuum systems are simpler but may deliver reduced assist in situations with low engine vacuum.

Performance Differences: Hydroboost vs Vacuum Boost

Hydroboost systems deliver greater stopping power and consistent brake performance, especially in heavy-duty vehicles and under high-load conditions, by utilizing hydraulic pressure from the power steering pump. Vacuum boost systems rely on engine vacuum to assist braking, which can diminish under heavy engine loads or turbocharged applications, leading to less effective brake assistance. Hydroboost offers improved pedal feel and reliability in demanding environments, making it preferable for trucks, SUVs, and vehicles with diesel engines, while vacuum boost remains common in lighter, gasoline-powered passenger cars.

Application Scenarios for Each System

Hydroboost systems are ideal for heavy-duty vehicles such as trucks and SUVs due to their reliance on hydraulic pressure from the power steering pump, providing consistent braking power even under high loads or engine-off conditions. Vacuum boost systems are more commonly used in passenger cars with gasoline engines where ample intake manifold vacuum is available, offering lightweight and cost-effective braking assistance for everyday driving. In scenarios involving diesel engines or vehicles with turbochargers that produce less vacuum, hydroboost systems ensure reliable performance compared to vacuum boost systems.

Advantages of Hydroboost Brake Systems

Hydroboost brake systems offer superior braking power by utilizing engine hydraulic pressure, making them more effective in vehicles with diesel engines or powertrains without sufficient vacuum supply. They provide consistent and reliable brake assist regardless of engine load or conditions, unlike vacuum boost systems that may falter under low vacuum scenarios such as turbocharged engines. Hydroboost systems enhance driver safety and control by delivering increased stopping force with minimal pedal effort, especially in heavy-duty or off-road applications.

Advantages of Vacuum Boost Brake Systems

Vacuum boost brake systems deliver consistent and reliable brake assist by utilizing engine vacuum, which reduces pedal effort and enhances driver control during braking. These systems are lightweight, simpler in design, and require less maintenance compared to hydraulic-based Hydroboost systems, making them cost-effective for standard passenger vehicles. Their efficiency excels in everyday driving conditions, providing smooth and predictable braking performance without the complexity of additional hydraulic components.

Common Issues and Maintenance Concerns

Hydroboost systems often face common issues like fluid leaks, worn seals, and air contamination, requiring regular inspection of hydraulic lines and fluid quality to maintain optimal performance. Vacuum boost systems frequently encounter problems such as vacuum leaks, diaphragm wear, and loss of vacuum pressure, necessitating routine checks of vacuum hoses, the check valve, and booster integrity. Both systems demand timely maintenance to prevent brake performance degradation, emphasizing fluid replacement for hydroboost and vacuum source verification for vacuum boost setups.

Choosing the Best Brake System for Your Vehicle

Hydroboost systems provide superior braking power by using hydraulic pressure from the power steering pump, making them ideal for vehicles with heavy-duty applications or diesel engines that lack sufficient engine vacuum. Vacuum boost systems rely on engine vacuum to assist braking, offering simplicity and cost-effectiveness suitable for light-duty and gasoline-powered vehicles. Selecting the best brake system depends on engine type, vehicle weight, and desired braking performance, with hydroboost excelling in high-demand scenarios and vacuum boost favoring everyday driving conditions.

caratoz.com

caratoz.com