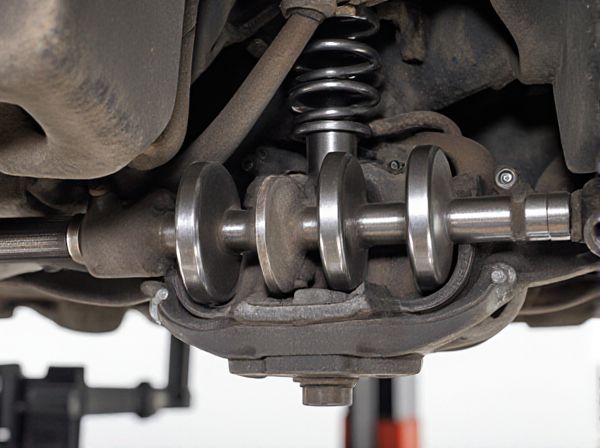

Photo illustration: High Lift vs Low Lift

High lift hair color delivers intense, vibrant results by lifting the natural pigment several levels, ideal for achieving bright blondes or bold shades. Low lift hair color gently enhances your base tone with subtle lightening or color changes, perfect for maintaining a natural look and minimizing damage. Your choice depends on the desired intensity and the health of your hair.

Table of Comparison

| Feature | High Lift Camshaft | Low Lift Camshaft |

|---|---|---|

| Valve Lift | Greater than 0.5 inches | Less than 0.5 inches |

| Performance | Improves high RPM power and torque | Optimizes low to mid RPM efficiency |

| Fuel Efficiency | Lower due to increased airflow | Higher, better fuel economy |

| Engine Wear | Increased stress, potential faster wear | Reduced stress, longer engine life |

| Application | High-performance, racing engines | Daily driving, economy-focused engines |

| Cost | Higher due to specialized design | Lower, standard replacement parts |

| Noise Level | Louder valve train noise | Quieter operation |

Understanding High Lift and Low Lift: Definitions

High lift refers to the aerodynamic condition in which a wing or airfoil generates a significant amount of lift at low speeds, often achieved through devices like flaps or slats that increase the wing's curvature and surface area. Low lift describes the aerodynamic state where a wing produces minimal lift, typically at higher speeds or with a clean wing configuration without lift-enhancing modifications. Understanding high lift and low lift is crucial for optimizing aircraft performance during takeoff, landing, and cruising phases by balancing lift generation and drag reduction.

Key Differences Between High Lift and Low Lift

High lift and low lift refer to different types of lifting equipment or mechanisms characterized by their maximum vertical reach and load capacity. High lift systems typically offer greater elevation, allowing for the handling of materials or tasks at elevated heights, often used in construction, warehousing, and manufacturing environments. Low lift equipment, in contrast, provides limited vertical movement but offers enhanced stability and maneuverability for operations close to the ground, making it ideal for tight spaces or lower-level tasks.

Advantages of High Lift Applications

High lift applications provide significant advantages in terms of increased productivity and efficiency by enabling the handling of larger loads at greater heights. These systems enhance operational safety and precision in industries such as construction and warehousing, allowing for improved access to elevated work areas. The robust design and extended reach capabilities of high lift equipment reduce manual labor requirements, resulting in faster project completion and lower labor costs.

Benefits of Low Lift Systems

Low lift systems offer significant energy efficiency advantages by requiring less power to move water or air over shorter vertical distances, reducing operational costs. These systems enable more precise pressure control and consistent flow rates, improving the performance of irrigation and HVAC networks. The reduced mechanical stress in low lift setups also leads to longer equipment lifespan and lower maintenance requirements.

Common Uses for High Lift vs Low Lift

High lift clippers are commonly used for styling long, thick hair and creating detailed designs due to their extended blade range and precision cutting capability. Low lift clippers are preferred for close, smooth shaves and tapering short hair, offering better control and a cleaner cut close to the scalp. Professionals in barbering and aesthetics select high lift clippers for volumizing techniques and low lift clippers for precise fades and skin-level trimming.

Performance Impact: High Lift vs Low Lift

High lift cams increase valve lift, allowing more air and fuel mixture into the combustion chamber, which significantly improves engine power and torque at higher RPMs. Low lift cams restrict valve opening, optimizing fuel efficiency and smoothness at lower engine speeds but limiting peak power output. The performance impact of high lift vs low lift hinges on balancing increased airflow and combustion efficiency against potential valve train stress and fuel consumption.

Maintenance and Longevity Comparison

High lift systems often require more frequent maintenance due to the increased mechanical complexity and stress on components, leading to higher long-term upkeep costs. Low lift systems generally experience less wear and tear, contributing to longer equipment lifespan and reduced maintenance intervals. Proper maintenance practices for both types significantly extend operational longevity but monitoring lift-specific wear patterns is crucial for optimal performance.

Cost Analysis: High Lift vs Low Lift

High lift systems generally incur higher initial installation costs due to complex equipment and energy demands, while low lift systems offer lower upfront expenses but may require more frequent maintenance and replacements. Operational costs for high lift pumps tend to be greater because of increased power consumption and wear on components, whereas low lift pumps operate more efficiently in shallow water applications, reducing energy expenses. Considering total cost of ownership, low lift solutions often provide cost savings for applications with minimal elevation requirements, but high lift systems are cost-effective for deep well pumping where greater vertical lift is essential.

Choosing the Right Lift for Your Needs

High lift equipment offers increased height and reach capabilities, making it ideal for industrial maintenance, construction, and tasks in hard-to-access areas. Low lift options prioritize stability and maneuverability, perfect for indoor projects and tight spaces where precise control is critical. Selecting the right lift depends on the specific height requirements, terrain conditions, and operational environment to enhance safety and efficiency.

Expert Tips for Optimal Lift Performance

High lift techniques require precise control of pressure and angle to maximize tensile strength without compromising material integrity, while low lift methods emphasize minimal force to preserve surface finish and prevent deformation. Experts recommend calibrating equipment to match specific material properties and conducting regular performance assessments to ensure consistent lift quality. Utilizing advanced sensors and adaptive algorithms can further optimize lift efficiency by dynamically adjusting parameters in real-time.

caratoz.com

caratoz.com