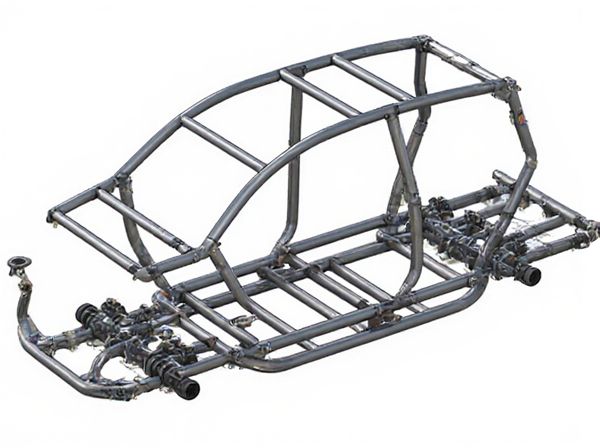

Photo illustration: Ladder Frame vs Tubular Frame

Ladder frames offer robust strength and durability, making them ideal for heavy-duty vehicles and off-road use due to their straightforward, rigid design. Tubular frames provide enhanced flexibility and weight reduction, improving handling and performance in sports cars and high-performance vehicles. Your choice depends on the specific application, balancing durability with agility requirements.

Table of Comparison

| Feature | Ladder Frame | Tubular Frame |

|---|---|---|

| Structure | Two parallel steel beams connected by cross members | Triangulated steel tubes forming a rigid cage |

| Weight | Heavier | Lighter |

| Rigidity | Moderate torsional rigidity | High torsional rigidity |

| Strength | High strength, ideal for heavy loads | High strength with optimized stress distribution |

| Flexibility | Less flexible in design | Highly adaptable to complex shapes |

| Applications | Trucks, SUVs, off-road vehicles | Racing cars, sports cars, custom builds |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Maintenance | Simpler, easier repairs | Complex repairs, requires specialized skills |

Introduction to Automotive Frame Designs

Ladder frames, composed of two longitudinal rails connected by several cross members, offer exceptional strength and durability, making them ideal for heavy-duty vehicles and off-road applications. Tubular frames utilize a network of interconnected tubes to create a lightweight yet rigid structure, enhancing vehicle agility and performance, especially in sports cars and race cars. Each frame design impacts vehicle weight distribution, crash safety, and manufacturing complexity, influencing the choice based on specific automotive engineering goals.

What is a Ladder Frame?

A ladder frame is a vehicle chassis design consisting of two parallel longitudinal beams connected by several lateral crossmembers, resembling a ladder's shape. It provides high structural rigidity and durability, making it ideal for heavy-duty vehicles such as trucks and SUVs. Commonly used in off-road and commercial applications, ladder frames excel in load-bearing capacity and ease of repair compared to tubular frames.

What is a Tubular Frame?

A tubular frame is a vehicle chassis construction composed of welded steel or aluminum tubes forming a rigid, lightweight skeleton to enhance structural integrity and crash resistance. Unlike the traditional ladder frame, which uses flat, rectangular sections, tubular frames provide superior torsional stiffness and improved handling characteristics, making them popular in high-performance and off-road vehicles. Their design allows for better weight distribution and customization, contributing to enhanced durability and overall vehicle dynamics.

Structural Differences: Ladder vs Tubular Frames

Ladder frames consist of two parallel steel beams connected by several cross members, providing a strong and durable foundation commonly used in trucks and SUVs for heavy-duty applications. Tubular frames use cylindrical tubes arranged in triangular patterns, offering superior rigidity and lighter weight ideal for high-performance and racing vehicles. The ladder frame excels in load-bearing capacity and repairability, while the tubular frame prioritizes torsional stiffness and weight reduction for enhanced handling and performance.

Strength and Durability Comparison

Ladder frames offer superior strength and durability, ideal for heavy-duty applications and off-road conditions due to their rigid, box-section design that resists torsional flex. Tubular frames provide enhanced structural integrity with lightweight construction, distributing stress evenly and improving resistance to fatigue and impact over time. Comparing both, ladder frames excel in load-bearing capacity and long-term robustness, while tubular frames optimize strength-to-weight ratio for dynamic performance and durability.

Weight Considerations in Each Frame Type

Ladder frames typically weigh more due to their heavy, box-section steel construction, offering increased rigidity but adding significant mass to the vehicle. Tubular frames are designed using lightweight steel or aluminum tubes, reducing overall weight while maintaining structural strength and enhancing vehicle agility. Weight considerations in frame selection directly impact fuel efficiency, handling, and load capacity, with tubular frames favored for performance applications and ladder frames preferred for heavy-duty durability.

Performance and Handling: Key Differences

Ladder frames offer superior rigidity and durability ideal for heavy-duty performance and off-road handling, providing enhanced stability under high loads. Tubular frames excel in lightweight construction, improving agility and responsiveness, which results in better cornering and overall handling dynamics. The choice between ladder and tubular frames directly influences vehicle performance characteristics, with ladder frames favoring robustness and tubular frames prioritizing precision and control.

Applications: When to Use Ladder or Tubular Frames

Ladder frames are ideal for heavy-duty vehicles like trucks and SUVs due to their excellent strength and durability under heavy loads and rough terrain. Tubular frames excel in high-performance and race cars, offering superior rigidity and reduced weight for enhanced handling and speed. Choosing between ladder and tubular frames depends on application requirements such as load capacity, vehicle type, and desired performance characteristics.

Cost and Manufacturing Complexity

Ladder frames typically offer lower manufacturing costs due to their simpler design and widespread availability of materials, making them suitable for budget-conscious vehicle production. Tubular frames involve higher manufacturing complexity as they require precision welding and specialized fabrication techniques, increasing labor and equipment expenses. The choice between ladder and tubular frames significantly impacts overall production costs and assembly time, with ladder frames favored for cost-efficiency and tubular frames for performance-driven applications.

Conclusion: Choosing the Right Frame for Your Vehicle

Selecting the ideal frame depends on vehicle purpose and performance needs; ladder frames offer superior durability and are preferred for heavy-duty trucks and off-road vehicles. Tubular frames provide enhanced rigidity and lighter weight, making them suitable for high-performance sports cars and custom builds. Evaluate factors like weight, strength, and intended use to determine the optimal frame that balances structural integrity and vehicle dynamics.

caratoz.com

caratoz.com