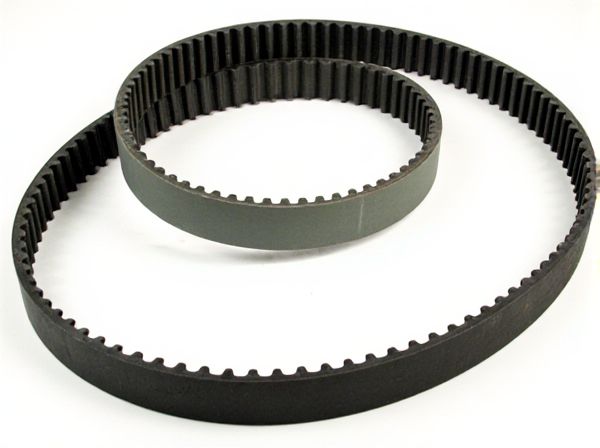

Photo illustration: Dry Belt vs Wet Belt

Dry belts, commonly used in abrasive applications, offer efficient dust control and reduced heat generation, making them ideal for woodworking and metal grinding. Wet belts utilize water or other lubricants to minimize friction and heat, extending the lifespan of the abrasive and improving finish quality on metals or ceramics. Choosing the right belt depends on your specific project requirements, balancing dust management, cooling needs, and material compatibility.

Table of Comparison

| Feature | Dry Timing Belt | Wet Timing Belt |

|---|---|---|

| Material | Reinforced rubber with fiberglass or Kevlar | Rubber with oil-resistant coatings |

| Operation Environment | Runs outside the engine oil system | Runs inside the engine oil environment |

| Durability | Typically lasts 60,000-100,000 miles | Enhanced lifespan, often 100,000+ miles |

| Maintenance | Regular replacement necessary to prevent failure | Longer intervals, less frequent replacement |

| Performance | Efficient power transmission, less heat resistance | Better heat and wear resistance due to oil lubrication |

| Common Use | Standard gasoline engines | Some modern engines with integrated oil systems |

| Cost | Generally lower initial cost | Higher initial cost but longer life reduces overall cost |

Introduction to Dry Belt and Wet Belt

Dry belts and wet belts serve distinct roles in material conveying systems, crucial for various industrial processes. Dry belts transport bulk solids without moisture, facilitating efficient handling of powders, grains, and pellets, while wet belts are engineered to convey materials immersed or coated in liquids, ensuring smooth movement in applications like wastewater treatment or slurry transportation. Understanding the operational differences between dry and wet belt conveyors is essential for optimizing performance, durability, and energy consumption in material handling systems.

Key Differences Between Dry Belts and Wet Belts

Dry belts operate in environments where materials are transported without moisture, relying on friction between the belt surface and the load to ensure efficient movement. Wet belts, in contrast, are designed to handle materials that involve water or other liquids, often incorporating specialized waterproof or corrosion-resistant materials to maintain durability and traction. Key differences include material composition, maintenance requirements, and suitability for specific industrial applications such as mining, construction, or wastewater treatment.

How Dry Belts Work

Dry belts operate by using friction between a textured belt surface and the material to effectively separate, convey, or screen particulate matter. The belt typically moves over rollers or a drum, driven by motorized pulleys, allowing dry materials like grains, powders, or aggregates to be transported without moisture interference. Their design minimizes residue buildup and promotes efficient material flow, making them ideal for applications requiring dry handling conditions.

How Wet Belts Function

Wet belts function by using a continuous flow of water along the conveyor surface to wash away dirt, debris, and contaminants from the conveyed materials, ensuring effective cleaning during transportation. This method enhances material handling in industries such as mining, recycling, and food processing by reducing dust and preventing material carryback. The water flow combined with the belt movement facilitates efficient separation and washing of materials, improving overall process hygiene and operational efficiency.

Advantages of Dry Belt Systems

Dry belt systems offer significant advantages including lower energy consumption due to the absence of water evaporation requirements, which leads to reduced operational costs. These systems minimize environmental impact by eliminating wastewater production and decreasing the risk of corrosion and equipment wear associated with moisture. Dry belt conveyors also enhance safety and cleanliness in industrial settings by preventing material spillage and contamination typically caused by wet conditions.

Benefits of Wet Belt Systems

Wet belt systems offer significant advantages in dust control and material handling by minimizing airborne dust emissions and reducing wear on equipment. These systems enhance dust suppression effectiveness through continuous water application, improving air quality and compliance with environmental regulations. The wet belt design also extends the lifespan of belts and rollers by reducing friction and heat, leading to lower maintenance costs and increased operational efficiency.

Maintenance Requirements: Dry vs Wet Belt

Dry belts require less frequent cleaning and are less prone to buildup of residue, resulting in lower maintenance demands compared to wet belts. Wet belts necessitate regular inspections for water damage, corrosion, and microbial growth, increasing maintenance efforts and costs. Proper lubrication and frequent monitoring of belt tension are critical tasks for wet belt upkeep to prevent operational failures.

Performance and Efficiency Comparison

Dry belt systems generally offer higher thermal efficiency due to reduced moisture content, resulting in faster drying times and lower energy consumption. Wet belt systems, while potentially slower, provide superior product quality for moisture-sensitive materials by maintaining controlled hydration levels throughout processing. Performance metrics indicate that dry belts excel in throughput and energy savings whereas wet belts optimize product texture and structural integrity.

Common Applications of Dry and Wet Belts

Dry belts are commonly used in manufacturing processes involving conveyor systems for material handling, packaging, and assembly lines where dust resistance and minimal maintenance are essential. Wet belts find widespread application in industries requiring cooling, lubrication, or washing during material transport, such as in food processing, metalworking, and mining operations. Both dry and wet belts are integral to optimizing production efficiency and ensuring the suitability of conveying solutions based on environmental and operational needs.

Choosing the Right Belt for Your Needs

Choosing the right belt between dry belts and wet belts depends on the specific requirements of your application, such as the environment, load capacity, and desired durability. Dry belts excel in dry, low-contamination settings with minimal maintenance, offering high friction and efficient power transmission. Wet belts perform better in humid or wet environments, providing superior heat dissipation and resistance to corrosion, which enhances longevity under harsh conditions.

caratoz.com

caratoz.com