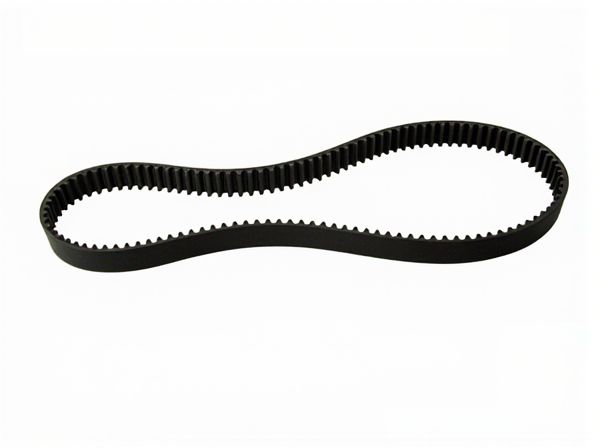

Photo illustration: High-Temperature Timing Belt vs Standard Temperature Timing Belt

High-temperature timing belts are engineered to withstand extreme heat conditions without losing flexibility or durability, making them ideal for engines exposed to higher operating temperatures. Standard temperature timing belts perform adequately under normal heat levels but may degrade faster in hotter environments, leading to potential belt failure. Selecting the appropriate belt ensures your engine maintains precise timing and optimal performance under varied temperature ranges.

Table of Comparison

| Feature | High-Temperature Timing Belt | Standard Temperature Timing Belt |

|---|---|---|

| Material Composition | Heat-resistant polymers and advanced composites | Standard rubber and fiber blends |

| Operating Temperature Range | Up to 150degC (302degF) | Up to 100degC (212degF) |

| Durability | Enhanced resistance to heat-induced wear and stretching | Moderate resistance, prone to faster degradation under heat |

| Lifespan | Typically 100,000 to 150,000 miles | Typically 50,000 to 70,000 miles |

| Ideal Application | High-performance engines, extreme climates | Standard engines, moderate operating conditions |

| Cost | Higher initial investment | Lower initial cost |

| Maintenance Frequency | Less frequent replacements required | More frequent replacements recommended |

Introduction to Timing Belts: High-Temperature vs Standard

High-temperature timing belts are engineered with advanced materials like heat-resistant rubber and reinforced fibers to withstand extreme thermal conditions up to 150degC, making them ideal for harsh environments in automotive and industrial applications. Standard temperature timing belts typically operate effectively within a range of -40degC to 90degC, offering reliable performance for general use where thermal stress is moderate. Selecting between high-temperature and standard belts depends on the specific operational temperature requirements and exposure conditions, ensuring optimal durability and timing accuracy in machinery.

Material Composition and Engineering Differences

High-temperature timing belts utilize advanced materials such as heat-resistant polyurethane and reinforced aramid fibers, allowing them to withstand temperatures above 150degC without degradation. Standard temperature timing belts are typically made from neoprene rubber combined with fiberglass cords, limiting their optimal operating range to around 100degC. Engineering differences include specialized heat treatments and contour designs in high-temperature belts to maintain tensile strength and flexibility under thermal stress, ensuring reliability in demanding industrial and automotive applications.

Temperature Resistance: Key Performance Factors

High-temperature timing belts are engineered to withstand extreme temperatures up to 250degC, utilizing advanced materials such as heat-resistant polymers and reinforced fibers to maintain structural integrity and prevent elongation. Standard temperature timing belts typically perform optimally within a temperature range of -30degC to 100degC, making them suitable for conventional automotive and industrial applications. The superior thermal resistance of high-temperature belts ensures consistent timing accuracy and longevity in demanding environments like aerospace, automotive turbochargers, and industrial machinery exposed to intense heat.

Common Applications for Each Belt Type

High-temperature timing belts are commonly used in automotive engines, industrial machinery, and aerospace applications where exposure to extreme heat and harsh environments is frequent, ensuring durability and reliable performance under thermal stress. Standard temperature timing belts find their primary applications in office equipment, light manufacturing, and household appliances where operating temperatures remain moderate and the demand for heat resistance is lower. Choosing the appropriate belt type depends on the specific temperature conditions and mechanical requirements of the machinery to optimize lifespan and efficiency.

Durability and Lifespan Comparison

High-temperature timing belts are engineered with advanced heat-resistant materials such as reinforced silicone or fluorocarbon rubber, allowing them to maintain structural integrity and flexibility in environments exceeding 150degC, significantly boosting durability. Standard temperature timing belts, typically made from neoprene or polyurethane, function optimally below 100degC and tend to degrade faster under thermal stress, resulting in a shorter lifespan. Consequently, high-temperature belts often offer a lifespan extension of 30-50% compared to standard belts, especially in automotive and industrial applications with elevated operating temperatures.

Maintenance Requirements and Best Practices

High-temperature timing belts require more frequent inspections due to their exposure to extreme heat, which accelerates material wear and reduces belt lifespan compared to standard temperature belts. Proper maintenance includes regular tension checks and timely replacements to prevent belt failure in high-heat environments. Using heat-resistant lubricants and ensuring adequate cooling can enhance durability and performance of high-temperature timing belts in demanding applications.

Cost Analysis: High-Temperature vs Standard Belts

High-temperature timing belts typically cost 20-30% more than standard temperature belts due to advanced materials that withstand heat up to 250degC, compared to standard belts rated for around 120degC. Despite the higher initial investment, high-temperature belts offer extended service life and reduced downtime in demanding engine environments, potentially lowering overall maintenance costs. Standard belts provide a cost-effective solution for less extreme conditions but may require more frequent replacements, increasing long-term expenses.

Impact on Machinery Efficiency and Reliability

High-temperature timing belts, made from heat-resistant materials such as silicone or reinforced rubber, maintain optimal tension and flexibility under extreme thermal conditions, thereby enhancing machinery efficiency by reducing slippage and energy loss. Standard temperature timing belts, typically composed of neoprene or polyurethane, may degrade faster in high-heat environments, leading to increased wear, frequent replacements, and potential downtime that compromises reliability. Investing in high-temperature timing belts improves operational lifespan and consistent performance in industrial applications exposed to elevated temperatures.

Choosing the Right Timing Belt for Your Needs

High-temperature timing belts are engineered with heat-resistant materials such as silicone or Viton, enabling them to maintain performance in extreme thermal environments up to 200degC, making them ideal for automotive engines or industrial machinery exposed to high heat. Standard temperature timing belts, typically made of neoprene or polyurethane, perform efficiently within normal operating temperatures up to 80degC and are cost-effective for general-purpose applications with moderate thermal stress. Selecting the right timing belt depends on evaluating operating temperature ranges, durability requirements, and compatibility with machinery specifications to ensure optimal performance and longevity.

Future Trends in Timing Belt Technology

High-temperature timing belts are engineered with advanced heat-resistant materials like fluororubber and reinforced fiberglass cords to withstand extreme operating environments, significantly enhancing longevity and performance compared to standard temperature timing belts. Future trends in timing belt technology emphasize the integration of smart sensors for real-time wear monitoring and the development of eco-friendly, bio-based polymers to improve sustainability and reduce environmental impact. Innovations such as self-lubricating coatings and nano-engineered composites are expected to set new industry standards, optimizing efficiency and maintenance cycles in automotive and industrial applications.

caratoz.com

caratoz.com