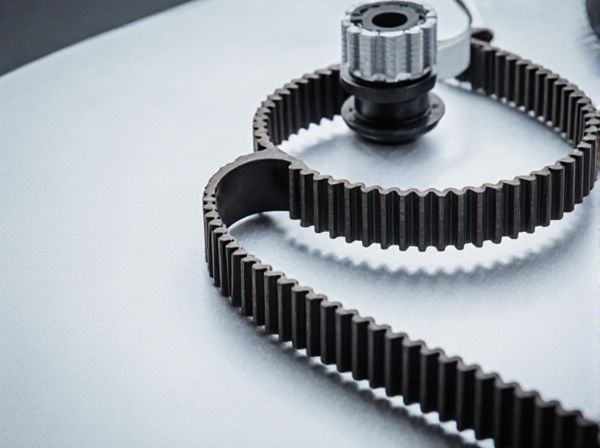

Photo illustration: Static Timing vs Dynamic Timing

Static timing analyzes the worst-case scenario of signal delays in digital circuits without relying on input patterns, ensuring reliable operation across all conditions. Dynamic timing, on the other hand, evaluates circuit performance based on specific input sequences, which can uncover timing violations missed by static analysis. Understanding both approaches helps you optimize circuit design for accuracy and efficiency under varying operational conditions.

Table of Comparison

| Feature | Static Timing | Dynamic Timing |

|---|---|---|

| Definition | Setting engine timing with the engine off | Adjusting timing while engine is running |

| Purpose | Initial synchronization of camshaft and crankshaft | Fine-tuning ignition and valve timing for performance |

| Tools Required | Timing light, dial gauge | Advanced timing light, computer diagnostic tools |

| Precision | Basic accuracy for setup | High precision for optimized engine performance |

| Timing Belt Role | Align camshaft and crankshaft pulleys | Allow dynamic adjustments without removal |

| Common Use | Engine assembly and major repairs | Tuning and diagnostics during operation |

| Advantages | Simple, cost-effective | Enhances engine efficiency and power |

| Limitations | Limited exactness, cannot account for running conditions | Requires expertise and specialized equipment |

Introduction to Timing Analysis

Static timing analysis examines the worst-case timing delays in a digital circuit without requiring simulation of input vectors, ensuring reliable performance under all operating conditions. Dynamic timing analysis uses input test vectors to simulate circuit behavior, capturing data-dependent delays and glitches but is limited by vector coverage. Accurate timing verification combines both methods to detect potential violations and optimize design performance.

Understanding Static Timing

Static timing analysis (STA) evaluates timing paths in digital circuits without requiring simulation of input vectors, providing a comprehensive assessment of worst-case delays and setup and hold times. It identifies timing violations by analyzing all possible paths based on circuit netlist and constraints, ensuring reliable operation under all conditions. STA is crucial for designing high-performance integrated circuits where timing accuracy and predictability directly impact chip functionality and yield.

Understanding Dynamic Timing

Dynamic timing refers to the evaluation of circuit performance based on actual signal transitions and data-dependent delays during operation, as opposed to static timing's worst-case scenario analysis. It considers real-time variations in input arrival times and path delays, providing a more precise model of timing behavior under functional conditions. This approach enables designers to identify critical timing paths influenced by dynamic factors, improving accurate timing closure and optimizing circuit speed.

Key Differences Between Static and Dynamic Timing

Static timing analysis evaluates circuit timing by examining worst-case scenarios without requiring input vector simulation, ensuring all timing paths meet constraints under all conditions. Dynamic timing analysis relies on simulating actual input vectors to measure timing behavior, capturing real operating conditions but potentially missing rare timing violations. The key difference lies in coverage accuracy versus comprehensive verification, with static timing offering exhaustive timing checks and dynamic timing providing detailed timing for specific scenarios.

Advantages of Static Timing

Static timing analysis offers comprehensive verification of all possible timing paths without requiring input vectors, ensuring faster and more predictable timing validation in integrated circuit design. It detects worst-case scenarios early in the design phase, reducing the risk of timing violations and improving design reliability. Unlike dynamic timing, static analysis scales efficiently with design complexity, making it ideal for modern high-speed digital circuits.

Advantages of Dynamic Timing

Dynamic timing offers superior adaptability in handling varying workloads and environmental conditions by continuously adjusting timing parameters in real-time. This approach enhances system performance and reliability, reducing the risk of timing violations caused by process variations and temperature fluctuations. As a result, dynamic timing enables more efficient power management and improved overall circuit robustness compared to static timing methods.

Limitations of Static Timing

Static timing analysis (STA) is limited by its conservative nature, which can lead to overly pessimistic timing estimates that fail to capture all real-world scenarios. It assumes worst-case process, voltage, and temperature variations, ignoring dynamic operating conditions and data-dependent delays. Consequently, STA may not detect timing failures caused by glitches or transition-dependent effects that dynamic timing analysis can identify.

Limitations of Dynamic Timing

Dynamic timing techniques often face limitations due to increased complexity in circuit design, leading to higher power consumption and reduced reliability under varying environmental conditions. These methods require precise clock distribution and synchronization, which can cause timing uncertainties and glitches, especially in high-frequency applications. Additionally, dynamic timing is more susceptible to noise and process variations, making it less predictable compared to static timing analysis.

Applications in Real-World Scenarios

Static timing analysis is widely used in digital circuit design for verifying timing constraints without executing the actual circuit, ensuring reliable operation in microprocessors and ASICs. Dynamic timing analysis applies in real-time system validation and high-speed communication circuits by simulating actual signal transitions and capturing timing variations under different operating conditions. Applications such as automotive safety systems and FPGA prototyping benefit from combining both methods to balance accuracy and computational efficiency in timing verification.

Choosing the Right Timing Approach

Choosing the right timing approach depends on the specific requirements of the system, with static timing analysis offering fixed worst-case delay guarantees ideal for safety-critical and real-time applications. Dynamic timing analysis provides detailed insights based on actual runtime conditions, making it suitable for systems where performance optimization and adaptability are essential. Evaluating factors such as system complexity, timing variability, and resource constraints is crucial in determining whether static or dynamic timing best meets design goals.

caratoz.com

caratoz.com