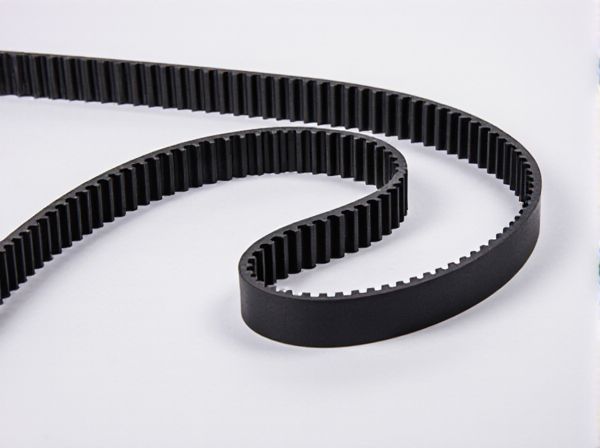

Photo illustration: Toothed Timing Belt vs Cogged Timing Belt

A toothed timing belt features evenly spaced, straight teeth designed for precise engine timing and smooth power transmission, making it ideal for high-performance scenarios. A cogged timing belt, with its notched or curved teeth, offers greater flexibility and can accommodate tighter pulley angles while maintaining efficient timing control. Your choice between the two depends on engine design requirements and desired durability.

Table of Comparison

| Feature | Toothed Timing Belt | Cogged Timing Belt |

|---|---|---|

| Design | Continuous teeth for precise engine timing | Indented cogs for enhanced flexibility |

| Material | Rubber with high-tensile fiber reinforcement | Rubber with notched edges and fiber layering |

| Performance | High accuracy, less belt stretch | Improved bending, reduced wear on pulleys |

| Durability | Long-lasting under standard conditions | Offers better heat dissipation, longer life in flexible routing |

| Applications | Precise timing in high-performance engines | Engines with complex pulley layouts requiring flexibility |

| Cost | Generally higher due to precision manufacturing | Usually more affordable with simpler design |

Introduction to Timing Belts

Timing belts are essential components in internal combustion engines, ensuring synchronized rotation between the crankshaft and camshaft. Toothed timing belts feature evenly spaced teeth designed for precise engagement with pulleys, while cogged timing belts have deeper, curved notches to improve flexibility and heat dissipation. Both types help prevent slippage and maintain engine timing, with the choice depending on specific performance and durability requirements.

What Is a Toothed Timing Belt?

A toothed timing belt is a crucial engine component featuring evenly spaced teeth that mesh with the camshaft and crankshaft sprockets to maintain precise engine timing. Constructed from durable materials like reinforced rubber or polyurethane, it ensures accurate synchronization of engine valves and pistons, preventing engine misfires and maintaining optimal performance. This belt's design provides superior grip and reduced slippage compared to smooth belts, making it essential for modern internal combustion engines.

What Is a Cogged Timing Belt?

A cogged timing belt features evenly spaced notches or teeth on the inner surface, designed to fit precisely with the corresponding teeth on pulleys, ensuring synchronized rotation and efficient power transmission in engines. Unlike standard toothed timing belts that have flat teeth, cogged timing belts enhance flexibility and reduce bending stress, improving belt life and performance in high-speed applications. These belts are commonly used in automotive engines and industrial machinery where precise timing and durability are critical.

Key Differences Between Toothed and Cogged Timing Belts

Toothed timing belts feature continuous, evenly spaced teeth designed to maintain precise synchronization between engine components, enhancing accuracy and reducing slippage risk. Cogged timing belts have deep, widely spaced grooves that offer increased flexibility and improved performance in high-torque applications by allowing better belt bending around smaller pulleys. The key differences lie in tooth profile, flexibility, and suitability for specific engine load conditions, with toothed belts excelling in precision and cogged belts in adaptability to variable loads.

Performance Comparison: Toothed vs Cogged Belts

Toothed timing belts feature continuous teeth that provide precise and smooth power transmission, minimizing slippage and noise, ideal for high-speed engine operations. Cogged timing belts have deeper notches that allow enhanced flexibility and heat dissipation, improving performance in applications with tighter pulley configurations and elevated temperature conditions. Performance comparisons highlight toothed belts excel in maintaining accurate timing under high loads, while cogged belts offer better bending fatigue resistance and quieter engagement.

Application Areas for Each Belt Type

Toothed timing belts are ideal for applications requiring precise synchronization and smooth operation, such as automotive engines, office machinery, and textile equipment, where low noise and high accuracy are critical. Cogged timing belts, designed for heavy-duty power transmission in industrial machinery, agricultural equipment, and conveyor systems, offer enhanced flexibility and load capacity under higher torque conditions. Each belt type's material composition and tooth design directly influence their suitability across varying operational environments and mechanical stresses.

Advantages of Toothed Timing Belts

Toothed timing belts offer superior precision in engine synchronization by ensuring consistent and slip-free power transmission, which enhances overall engine efficiency and performance. Their durability and resistance to wear under high-tension conditions make them ideal for long-term use in demanding automotive and industrial applications. The quieter operation and lower maintenance requirements of toothed timing belts reduce downtime and improve reliability compared to cogged timing belts.

Benefits of Cogged Timing Belts

Cogged timing belts provide enhanced flexibility and improved efficiency by reducing bending resistance, allowing smoother operation in tight pulley configurations. Their design increases heat dissipation and minimizes wear, extending belt lifespan and maintenance intervals. These belts also offer superior grip and reduced slippage compared to traditional toothed belts, improving overall system reliability.

Maintenance and Longevity Considerations

Toothed timing belts require routine inspection for wear and tension to prevent slippage, ensuring consistent engine timing and extended lifespan. Cogged timing belts offer improved flexibility and heat dissipation, reducing the risk of premature cracking and enabling longer service intervals. Proper maintenance of both belt types involves timely replacement according to manufacturer recommendations, crucial for avoiding catastrophic engine damage and maximizing durability.

Choosing the Right Timing Belt for Your Application

Toothed timing belts offer precise synchronization and are ideal for high-speed, high-torque applications requiring minimal backlash. Cogged timing belts provide improved flexibility and reduced bending stress, making them better suited for smaller pulleys and lighter loads. Selecting the right timing belt depends on factors such as load requirements, pulley size, operating speed, and desired belt longevity.

caratoz.com

caratoz.com