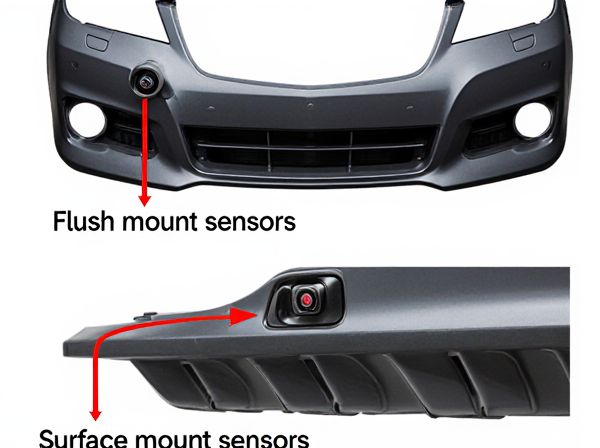

Photo illustration: Flush mount sensors vs Surface mount sensors

Flush mount sensors are embedded directly into a surface, allowing them to detect objects without obstruction and minimizing interference from surrounding materials. Surface mount sensors are installed on the surface, offering easier installation and adjustment but may suffer from reduced sensing range and increased vulnerability to damage. Choosing between the two depends on your application's space constraints, environmental conditions, and required detection accuracy.

Table of Comparison

| Feature | Flush Mount Sensors | Surface Mount Sensors |

|---|---|---|

| Installation | Embedded into bumper for seamless integration | Mounted on bumper surface, easy to install |

| Aesthetics | Sleek, minimal visibility | Visible, bulkier appearance |

| Durability | Protected from impacts and dirt | More exposed to damage and debris |

| Sensor Range | Consistent range, unaffected by protrusion | May have limited range due to placement |

| Cost | Higher due to complex installation | Lower, simpler installation process |

| Maintenance | Less frequent, harder to access | Easy access, more frequent cleaning |

| Common Use | High-end vehicles, factory OEM fitment | Aftermarket upgrades, budget-friendly options |

Introduction to Flush Mount and Surface Mount Sensors

Flush mount sensors are embedded directly into a surface, allowing them to detect objects without protruding, ideal for applications requiring minimal interference and high protection against environmental factors. Surface mount sensors are installed on the surface, offering easier installation and maintenance with broader sensing ranges but increased exposure to potential damage. Choosing between flush and surface mount sensors depends on specific application needs such as space constraints, durability, and sensing distance.

Key Differences Between Flush and Surface Mount Sensors

Flush mount sensors are designed to be installed level with the mounting surface, enabling them to detect objects directly in front without interference, making them ideal for applications requiring precise object detection in confined spaces. Surface mount sensors protrude from the mounting surface, offering a longer detection range but increased susceptibility to false triggers due to side object interference. Key differences include installation depth, sensing range, environmental robustness, and susceptibility to damage; flush mount sensors provide better immunity to surrounding objects, while surface mount sensors accommodate extended sensing distances with more flexible positioning.

Advantages of Flush Mount Sensors

Flush mount sensors offer superior protection against environmental factors such as dust, moisture, and mechanical damage due to their embedded installation within surfaces. This design minimizes false readings caused by foreign objects or contaminants, enhancing measurement accuracy and reliability in harsh industrial environments. Moreover, flush mount sensors maintain a smooth surface, reducing interference with material flow and simplifying cleaning processes in applications like processing lines and automation systems.

Advantages of Surface Mount Sensors

Surface mount sensors offer enhanced versatility by detecting objects through non-metallic materials, enabling installation on various surfaces without compromising sensor integrity. Their ease of installation and alignment reduces setup time and maintenance efforts, making them ideal for dynamic industrial environments. Surface mount sensors also provide better resistance to hostile conditions, such as dirt and moisture, due to their protected housing design.

Installation Requirements for Each Sensor Type

Flush mount sensors require precise embedding within the mounting surface, ensuring the sensing face is level with the surrounding material to avoid detection interference and maintain sensor accuracy. Surface mount sensors are externally mounted on the surface, allowing easier installation without the need for cutting into the mounting structure, which reduces setup time and installation complexity. Proper alignment and secure fastening are critical for both types to maintain optimal sensor performance and reliability in various industrial applications.

Performance Comparison: Flush vs Surface Mount Sensors

Flush mount sensors provide higher accuracy and better resistance to environmental contaminants due to their embedded design, ideal for precise proximity detection in harsh conditions. Surface mount sensors offer easier installation and flexibility in positioning but may suffer from reduced sensitivity and increased exposure to dirt and debris, impacting long-term reliability. Performance comparison highlights flush mount sensors as superior for demanding applications where precision and durability are critical.

Typical Applications for Flush Mount Sensors

Flush mount sensors are ideal for environments requiring minimal sensor intrusion, such as packaging machinery, conveyor systems, and automated assembly lines where accurate object detection without physical obstructions is critical. These sensors excel in detecting metallic and non-metallic objects embedded within or behind surfaces, making them suitable for applications in material handling, automotive manufacturing, and robotics. Their ability to operate seamlessly in confined spaces enhances operational efficiency and reduces the risk of sensor damage in harsh industrial settings.

Typical Applications for Surface Mount Sensors

Surface mount sensors are commonly used in applications requiring detection of objects with irregular shapes or materials that might interfere with flush mount sensor performance, such as in packaging, conveyor systems, and robotic pick-and-place operations. These sensors excel in environments where non-metallic or transparent objects must be detected reliably, including food processing and pharmaceutical industries. Their design allows for greater sensing distances and flexibility in installation compared to flush mount sensors, making them suitable for diverse industrial automation tasks.

Factors to Consider When Choosing Sensor Type

Flush mount sensors provide seamless integration into machinery, ideal for applications requiring protection against dirt, dust, and physical damage, while surface mount sensors offer easier installation and maintenance with protruding sensing faces. Key factors to consider include the sensor's environment, required sensing distance, and susceptibility to contamination or mechanical impact. Selection depends on balancing protection needs, sensor sensitivity, and installation constraints for optimal performance.

Conclusion: Which Sensor Type is Best for Your Needs?

Flush mount sensors offer a sleek installation with minimal disruption to the surface, ideal for environments requiring protection from debris or tampering. Surface mount sensors provide easier installation and maintenance with higher sensitivity, making them suitable for applications needing quick setup and optimal detection range. Choosing between flush mount and surface mount sensors depends on specific operational requirements such as environmental exposure, space constraints, and detection sensitivity priorities.

caratoz.com

caratoz.com