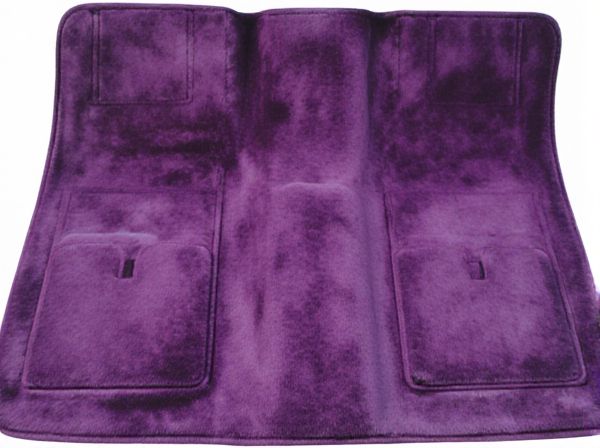

Photo illustration: Colorfast Dyeing vs Standard Dyeing

Colorfast dyeing ensures that fabrics retain vibrant colors even after multiple washes, making your garments more durable and resistant to fading. Standard dyeing may result in colors that fade quickly or bleed during laundering, reducing the overall lifespan and appearance of the fabric. Choosing colorfast dyeing improves the longevity and quality of textiles, offering better value and satisfaction.

Table of Comparison

| Feature | Colorfast Dyeing | Standard Dyeing |

|---|---|---|

| Color Retention | High resistance to fading | Moderate fading over time |

| Durability | Enhanced longevity and wear resistance | Average durability |

| UV Resistance | Strong protection against UV damage | Limited UV protection |

| Cost | Higher initial cost | More budget-friendly |

| Environmental Impact | Eco-friendly dyeing process | Conventional chemical dyeing |

| Application | Used for premium car carpets | Common in standard car carpets |

Introduction to Textile Dyeing Methods

Colorfast dyeing techniques ensure long-lasting color retention by using reactive or acid dyes that chemically bond with textile fibers, reducing fading and bleeding during washes. Standard dyeing methods typically involve direct or vat dyes that may not fully penetrate fibers, leading to color loss over time and lower resistance to environmental factors. Selecting between colorfast and standard dyeing impacts fabric durability, aesthetic quality, and end-use performance in textile production.

What is Standard Dyeing?

Standard dyeing is a traditional textile coloring process in which fibers or fabrics are treated with dyes to achieve desired hues, often resulting in variable colorfastness depending on the dye type and fabric composition. This method typically involves immersion or padding techniques that may lead to uneven dye penetration and reduced durability under washing or light exposure. Standard dyeing contrasts with colorfast dyeing by generally exhibiting lower resistance to fading, bleeding, and washing degradation.

Understanding Colorfast Dyeing Techniques

Colorfast dyeing techniques utilize reactive, vat, and acid dyes that chemically bond with fabric fibers to ensure long-lasting color retention and resistance to fading from washing and sunlight. These methods often involve higher temperature and pH control during the dyeing process to improve dye fixation and durability compared to standard dyeing, which primarily relies on physical absorption of dyes. Advanced colorfast dyeing technologies enhance fabric performance, making them ideal for textiles requiring high wash fastness and color consistency.

Key Differences Between Colorfast and Standard Dyeing

Colorfast dyeing ensures that fabrics maintain their original color intensity and resist fading or bleeding, making it ideal for high-quality, durable textiles. Standard dyeing often results in less color retention and increased susceptibility to fading during washing and exposure to sunlight. The key differences lie in dye fixation techniques, with colorfast dyeing utilizing advanced chemical processes for enhanced pigment binding compared to conventional methods used in standard dyeing.

Benefits of Colorfast Dyeing

Colorfast dyeing offers superior durability by ensuring colors remain vibrant and resistant to fading even after multiple washes and prolonged exposure to sunlight. This dyeing technique enhances fabric quality, reducing the risk of bleeding and maintaining color consistency across different textile materials. By minimizing color loss, colorfast dyeing extends the lifespan of garments, promoting sustainability and reducing the need for frequent replacements.

Limitations of Standard Dyeing Processes

Standard dyeing processes often suffer from limited color durability, leading to rapid fading and poor wash fastness, which reduces garment lifespan. These methods typically involve higher water and energy consumption, contributing to environmental concerns and increased production costs. Inconsistent dye penetration and color uniformity further restrict the quality and performance of textiles compared to advanced colorfast dyeing techniques.

Impact on Fabric Quality and Longevity

Colorfast dyeing significantly enhances fabric quality by ensuring deeper dye penetration, which reduces fading and color bleeding over time. Standard dyeing often results in surface-level color that diminishes quickly with washing and exposure to sunlight, compromising fabric longevity. Fabrics dyed using colorfast techniques maintain vibrancy and structural integrity longer, offering superior durability and sustained appearance.

Environmental Implications of Dyeing Methods

Colorfast dyeing significantly reduces water consumption and chemical waste compared to standard dyeing methods, which often require multiple rinses and substantial water usage. Standard dyeing processes release higher levels of hazardous pollutants and untreated effluents into waterways, contributing to environmental degradation and toxicity in aquatic ecosystems. The adoption of colorfast dyeing techniques promotes sustainability by minimizing harmful waste discharge and conserving natural resources.

Cost Comparison: Colorfast vs Standard Dyeing

Colorfast dyeing typically incurs higher initial costs compared to standard dyeing due to the use of advanced chemicals and processes that ensure enhanced durability and resistance to fading. Although standard dyeing is more economical upfront, it often results in shorter garment lifespan and increased costs associated with fading and recoloring over time. Investing in colorfast dyeing can lead to long-term savings by reducing the need for frequent maintenance and replacement.

Choosing the Right Dyeing Method for Your Needs

Colorfast dyeing delivers superior resistance to fading, making it ideal for textiles exposed to frequent washing and sunlight, while standard dyeing offers cost-effective solutions for less demanding applications. Selecting the right dyeing method depends on the fabric type, desired durability, and budget constraints, with colorfast techniques favored for performance fabrics and high-wear items. Evaluating the end-use environment and maintenance requirements ensures optimal color retention and consumer satisfaction.

caratoz.com

caratoz.com