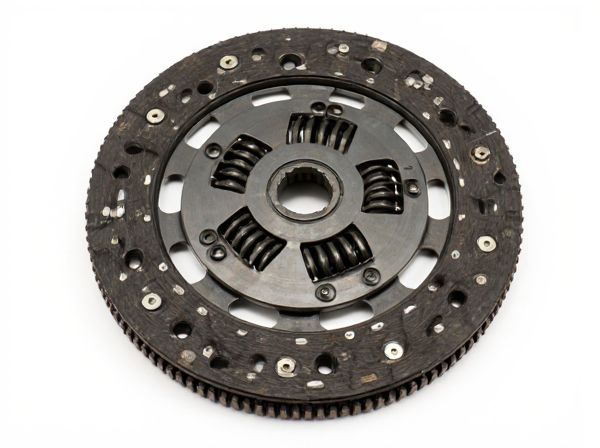

Photo illustration: Single Plate Clutch vs Twin Plate Clutch

A single plate clutch offers simpler design, lighter weight, and easier maintenance, making it ideal for everyday city driving and moderate power applications. Twin plate clutches provide increased friction surface area, allowing for higher torque capacity and improved performance in high-power or racing vehicles. Your choice depends on balancing driving style, vehicle power, and maintenance preferences.

Table of Comparison

| Feature | Single Plate Clutch | Twin Plate Clutch |

|---|---|---|

| Design | One friction plate | Two friction plates |

| Torque Capacity | Lower torque handling | Higher torque handling |

| Size | Compact and lighter | Larger and heavier |

| Heat Dissipation | Less efficient | Improved heat dissipation |

| Wear and Durability | Faster wear under heavy load | Better durability for performance use |

| Cost | Generally cheaper | More expensive due to complexity |

| Application | Standard cars, light vehicles | High-performance cars, racing vehicles |

| Pedal Effort | Lower pedal effort | Higher pedal effort |

Introduction to Single Plate and Twin Plate Clutches

Single plate clutches feature a single friction disc that engages with the flywheel to transmit power, offering simplicity and ease of maintenance ideal for everyday vehicles. Twin plate clutches use two friction discs, providing increased surface area for better torque handling and improved heat dissipation, making them suitable for high-performance or heavy-duty applications. Both types play crucial roles in manual transmission systems, balancing factors like grip, durability, and responsiveness according to vehicle demands.

Basic Working Principle of Clutch Systems

The single plate clutch operates with one friction disc pressed between the engine flywheel and pressure plate, transmitting power through the friction generated when engaged. Twin plate clutches use two friction discs, increasing the contact surface area and torque capacity while maintaining compact design. Both systems rely on disengaging the engine from the transmission to enable smooth gear changes by temporarily interrupting power flow.

Key Components: Single Plate vs Twin Plate

Single plate clutches use one friction disc pressed between two plates to transfer power, offering simplicity and lighter weight ideal for everyday driving and moderate torque. Twin plate clutches incorporate two friction discs and three pressure plates, providing increased surface area for better heat dissipation and higher torque capacity, suitable for performance and heavy-duty applications. The twin plate design also results in smoother engagement and improved durability under stress compared to single plate counterparts.

Performance Differences Explained

Single plate clutches provide smoother engagement and are typically lighter, making them ideal for everyday driving and moderate power applications. Twin plate clutches offer higher torque capacity and better heat dissipation, which enhances performance and durability in high-power or racing vehicles. The choice between single and twin plate clutches significantly impacts vehicle acceleration, drivability, and overall clutch lifespan under demanding conditions.

Advantages of Single Plate Clutch

Single plate clutches boast a simpler design, resulting in lower manufacturing costs and easier maintenance compared to twin plate clutches. They offer reliable performance in smaller engines and light-duty vehicles due to their efficient torque transfer and reduced frictional losses. The compact size of single plate clutches contributes to lighter drivetrain components, enhancing fuel efficiency and improving overall vehicle handling.

Benefits of Twin Plate Clutch

Twin plate clutches offer enhanced torque capacity and improved heat dissipation compared to single plate clutches, making them ideal for high-performance and heavy-duty applications. The dual friction surfaces increase the contact area, resulting in smoother power transmission and reduced clutch slippage. This design also allows for a more compact clutch assembly without compromising strength, providing better durability and reliability under demanding conditions.

Applications: Where Each Clutch Excels

Single plate clutches excel in everyday passenger vehicles and light trucks due to their simplicity, cost-effectiveness, and ease of maintenance, providing smooth engagement suitable for city driving and moderate load conditions. Twin plate clutches are preferred in high-performance sports cars, heavy-duty vehicles, and racing applications where they deliver greater torque capacity, improved heat dissipation, and enhanced durability under extreme stress. While single plate clutches optimize fuel efficiency and comfort, twin plate clutches prioritize performance and reliability in demanding environments.

Maintenance and Longevity Comparison

Single plate clutches generally require less frequent maintenance due to their simpler design, leading to lower repair costs over time. Twin plate clutches provide higher torque capacity and better performance under heavy loads but may experience faster wear, necessitating more regular inspections and adjustments. Both clutch types benefit from timely oil changes and proper usage to maximize longevity, with twin plate systems often demanding meticulous maintenance for optimal durability.

Cost Considerations and Value for Money

Single plate clutches typically offer lower initial costs and simpler maintenance, making them more budget-friendly for everyday vehicles. Twin plate clutches, despite higher upfront expenses, deliver enhanced performance and durability, providing better value for money in high-demand or performance applications. Evaluating long-term reliability and driving conditions is crucial to balance cost with functionality in clutch selection.

Choosing the Right Clutch for Your Vehicle

Single plate clutches offer simplicity, lower cost, and are ideal for everyday driving with moderate power vehicles, ensuring smooth engagement and durability. Twin plate clutches provide higher torque capacity and improved heat dissipation, making them suitable for performance cars, heavy-duty vehicles, or those requiring enhanced grip and quicker response. Selecting the right clutch depends on your vehicle's power output, driving style, and load conditions to optimize performance and longevity.

caratoz.com

caratoz.com