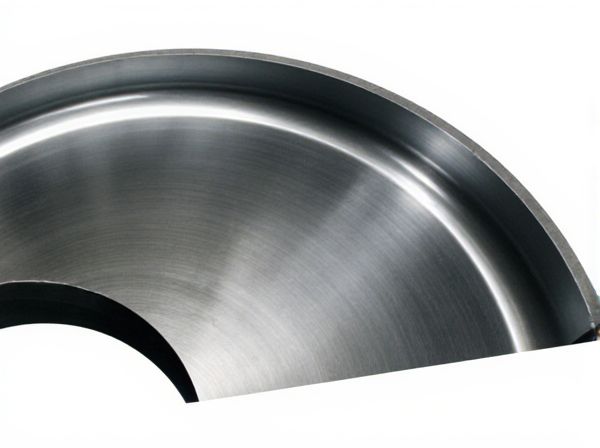

Photo illustration: Hypoid vs Spiral Bevel

Hypoid gears provide smoother and quieter operation due to their offset design, allowing for higher torque transmission and better durability in automotive differentials. Spiral bevel gears offer precise angular movement and efficiency, making them ideal for applications requiring accurate direction changes at right angles. Understanding the differences helps you select the appropriate gear type based on load capacity, noise level, and space constraints.

Table of Comparison

| Feature | Hypoid Differential | Spiral Bevel Differential |

|---|---|---|

| Gear Design | Offset pinion shaft, spiral-shaped gears | Aligned pinion shaft, spiral-shaped gears |

| Torque Capacity | Higher torque handling due to larger gear surface area | Lower torque capacity compared to hypoid |

| Noise & Vibration | Quieter operation with smoother gear engagement | More noise and vibration under load |

| Lubrication | Requires heavy-duty gear oil due to sliding contact | Uses standard gear oil, less sliding friction |

| Efficiency | Lower mechanical efficiency from sliding action | Higher mechanical efficiency, less power loss |

| Application | Common in rear-wheel drive and trucks for durability | Used in performance and some front-wheel drive vehicles |

| Cost | More expensive due to complex design and manufacturing | Less costly, simpler construction |

Overview: Hypoid vs Spiral Bevel Gears

Hypoid gears feature an offset axis, allowing smoother meshing and higher torque transmission compared to spiral bevel gears, which have intersecting axes and provide precise angular motion transfer. The unique design of hypoid gears results in quieter operation and increased load capacity, making them ideal for automotive differentials. Spiral bevel gears excel in efficiency and compactness, commonly used in applications requiring accurate, moderate torque transfer with less noise sensitivity.

Fundamental Gear Design Differences

Hypoid gears feature an offset axis between the pinion and ring gear, allowing for higher torque transmission and smoother operation due to larger contact areas and sliding action. Spiral bevel gears have intersecting axes with curved teeth that provide rapid speed changes and efficient power transfer but generate more noise and require precise alignment. The fundamental design difference lies in the hypoid's offset geometry enabling enhanced durability, while spiral bevel gears prioritize angular velocity change with simpler mounting constraints.

Operating Principles of Hypoid Gears

Hypoid gears operate with axes that are offset and non-intersecting, allowing for smoother and quieter power transmission compared to spiral bevel gears whose axes intersect. The hypoid gear's unique sliding action between the pinion and gear teeth reduces noise and increases torque capacity, making them ideal for automotive differentials. Their operating principle involves the hypoid pinion engaging the large hypoid ring gear at an offset, combining rolling and sliding motion to efficiently transfer power at varied angles.

Operating Principles of Spiral Bevel Gears

Spiral bevel gears operate by transmitting torque between intersecting shafts at a right angle, featuring curved, spiral-shaped teeth that allow gradual tooth engagement and smooth power transfer. Their operating principles rely on precise meshing of spiral teeth, which reduces noise and vibration while enhancing load distribution across the gear surface. This design improves gear efficiency and durability compared to straight bevel gears, making spiral bevels ideal for automotive differentials and industrial machinery.

Comparative Efficiency and Power Transmission

Hypoid gears exhibit higher efficiency and smoother power transmission compared to spiral bevel gears due to their sliding contact, which reduces noise and increases torque capacity in automotive differentials. Spiral bevel gears offer precise angular power transfer with less axial load but generally have lower load capacity and efficiency at high speeds. The hypoid design's offset shafts enable larger pinion diameters, resulting in improved durability and enhanced power handling for heavy-duty applications.

Load Capacity and Durability Analysis

Hypoid gears exhibit higher load capacity and superior durability compared to spiral bevel gears due to their sliding contact and larger contact area, which distribute stress more evenly across the gear teeth. The offset axes design of hypoid gears reduces noise and vibration while enhancing torque transmission efficiency, making them ideal for heavy-duty applications. Spiral bevel gears, though efficient for moderate loads, typically experience greater wear and lower load capacity because of their point contact and limited tooth engagement surface.

Noise, Vibration, and Smoothness Assessment

Hypoid gears are characterized by lower noise and vibration levels compared to spiral bevel gears due to their sliding contact and larger contact area, which enhances smoothness during operation. Spiral bevel gears generate higher noise and vibration owing to their rolling contact and smaller tooth engagement, potentially reducing overall smoothness under load. Noise and vibration assessments consistently show hypoid gears providing quieter and smoother performance in automotive and industrial applications.

Applications in Automotive and Industrial Sectors

Hypoid gears are extensively used in automotive differentials for their ability to handle high torque loads and provide smoother, quieter operation compared to spiral bevel gears. Spiral bevel gears find wide application in industrial machinery requiring precise angle transmission and high-speed performance, such as aerospace actuators and heavy equipment. The unique offset axis of hypoid gears allows for more compact design and improved efficiency in automotive drivetrains, while spiral bevel gears excel in applications demanding exact alignment and lower axial thrust.

Maintenance, Lubrication, and Lifespan Considerations

Hypoid gears require specialized high-pressure, extreme-pressure (EP) lubricants to maintain optimal performance and prevent wear, whereas spiral bevel gears typically utilize standard gear oils with moderate EP additives. Maintenance for hypoid gears involves regular inspection for lubricant contamination and oil level checks due to their higher load capacity and sliding action, which generates more heat and friction, impacting lifespan. Spiral bevel gears generally experience less sliding friction, resulting in longer intervals between lubrication changes and potentially extended service life if properly maintained.

Choosing the Right Gear: Key Selection Criteria

Selecting the right gear between hypoid and spiral bevel hinges on factors such as load capacity, noise levels, and shaft positioning. Hypoid gears excel in transmitting higher torque with quieter operation due to their offset axes, making them ideal for automotive differentials. Spiral bevel gears, with intersecting shafts and precise angular alignment, offer superior efficiency in low-speed applications requiring smooth power transmission.

caratoz.com

caratoz.com