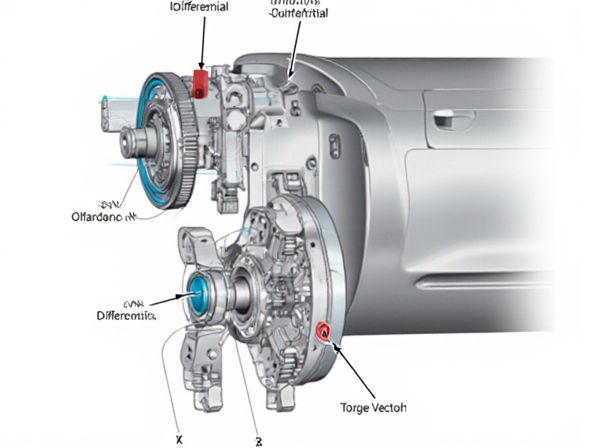

Photo illustration: Torque Vectoring Differential vs Standard Differential

A torque vectoring differential enhances vehicle handling by distributing power dynamically to individual wheels, improving traction and cornering performance compared to a standard differential that simply splits torque evenly. This technology adjusts torque based on driving conditions, offering better stability and control, especially on slippery or uneven surfaces. Your driving experience becomes more responsive and safer with torque vectoring, particularly in high-performance or off-road scenarios.

Table of Comparison

| Feature | Torque Vectoring Differential | Standard Differential |

|---|---|---|

| Function | Distributes torque between wheels for improved traction and handling | Equally splits torque, allowing wheels to rotate at different speeds |

| Performance | Enhances cornering stability and reduces understeer | Basic traction, less effective in sharp turns |

| Traction | Optimizes grip on slippery or uneven surfaces | Limited grip control during wheel slip |

| Complexity | Advanced mechanical or electronic system | Simple mechanical design |

| Cost | Higher cost due to technology and components | Lower cost, widely used in standard vehicles |

| Use Case | Sports cars, off-road vehicles, and performance driving | Everyday passenger cars and basic drivetrains |

Introduction to Automotive Differentials

Automotive differentials play a crucial role in distributing engine torque to the wheels while allowing them to rotate at different speeds, especially during turns. A standard differential splits torque evenly but can lead to wheel slip under low traction conditions. Torque vectoring differentials enhance vehicle handling and stability by actively directing torque to individual wheels based on driving conditions, improving cornering performance and traction control.

What Is a Standard Differential?

A standard differential is a mechanical component in vehicles that allows wheels on the same axle to rotate at different speeds, essential for smooth cornering and handling. It distributes engine torque equally to both wheels, but lacks the ability to actively control torque distribution based on traction conditions, which can lead to wheel slip on slippery surfaces. Unlike torque vectoring differentials, standard differentials do not provide enhanced stability or performance improvements during dynamic driving scenarios.

How Torque Vectoring Differential Works

Torque vectoring differential enhances vehicle handling by dynamically distributing torque between the wheels, improving traction and stability during cornering. Unlike standard differentials that split power evenly, torque vectoring adjusts torque flow based on sensor inputs like wheel speed, steering angle, and vehicle yaw to optimize grip. This precise control reduces understeer and oversteer, providing superior cornering performance and improved overall driving dynamics.

Key Differences Between Standard and Torque Vectoring Differentials

Torque vectoring differentials actively manage power distribution between wheels to enhance traction and cornering performance, contrasting with standard differentials that simply allow wheels to rotate at different speeds. Torque vectoring systems use sensors and electronic controls to apply torque selectively, improving stability and handling, especially in high-performance or off-road vehicles. Standard differentials are mechanical devices primarily designed for smooth cornering, lacking the dynamic torque distribution capabilities found in torque vectoring differentials.

Performance Benefits of Torque Vectoring Differential

Torque vectoring differentials enhance vehicle performance by actively distributing torque to individual wheels, improving traction and cornering stability compared to standard differentials that split torque evenly across an axle. This technology enables faster acceleration out of corners and reduces understeer by optimizing wheel grip based on real-time driving conditions. Advanced systems increase handling precision and driver control, especially in high-performance and AWD vehicles, resulting in superior agility and safety on varied road surfaces.

Handling and Traction Comparison

Torque vectoring differentials enhance handling by actively distributing torque between wheels, improving cornering stability and reducing understeer compared to standard differentials that provide uniform torque distribution. This technology maximizes traction on slippery or uneven surfaces by sending power to the wheel with the most grip, whereas standard differentials can cause power loss through wheel slip. Vehicles equipped with torque vectoring differentials exhibit superior agility and control, especially in dynamic driving conditions, outperforming the traction and handling capabilities of standard differential systems.

Efficiency and Fuel Economy Considerations

Torque vectoring differentials improve vehicle efficiency by actively distributing power to the wheels with the most grip, enhancing traction and reducing energy loss compared to standard differentials that split torque evenly regardless of conditions. This targeted power distribution minimizes wheel slip and drivetrain resistance, leading to better fuel economy, especially in dynamic driving scenarios or slippery conditions. Standard differentials often result in torque wastage due to constant power splitting, which can negatively impact fuel efficiency during acceleration and cornering.

Common Applications in Modern Vehicles

Torque vectoring differentials are commonly found in high-performance sports cars and advanced all-wheel-drive systems, enhancing cornering stability and traction by independently distributing torque between wheels. Standard differentials are widely used in everyday passenger cars and light trucks, allowing wheels to rotate at different speeds during turns to ensure smoother handling. Modern electric and hybrid vehicles increasingly incorporate torque vectoring to optimize power delivery and improve driving dynamics under varied road conditions.

Maintenance and Reliability Factors

Torque vectoring differentials generally require more complex components and advanced electronics, resulting in higher maintenance costs compared to standard differentials. Standard differentials feature simpler mechanical designs, making them typically more reliable and easier to service over time. Vehicle owners seeking lower long-term maintenance expenses often prefer standard differentials due to fewer failure points and more widely available replacement parts.

Which Differential Suits Your Driving Needs?

Torque vectoring differentials enhance cornering performance by actively distributing torque between wheels, improving traction and handling on varying road conditions. Standard differentials offer a simpler, cost-effective solution suitable for everyday driving and moderate performance needs without the complexity of active torque management. Choosing the right differential depends on your driving style: torque vectoring suits enthusiasts seeking precision and dynamic control, while standard differentials cater to drivers prioritizing reliability and affordability.

caratoz.com

caratoz.com