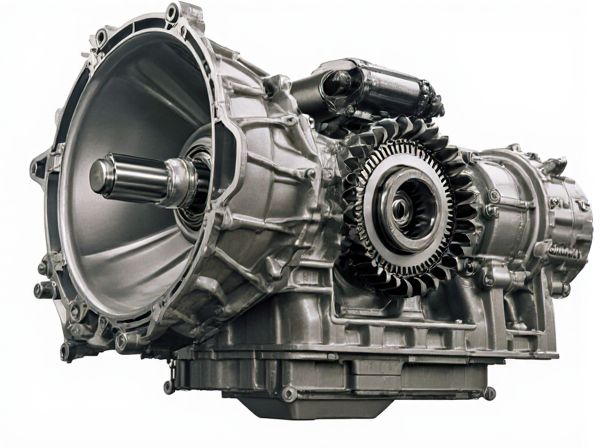

Photo illustration: Planetary gearset vs Lay shaft

A planetary gearset offers compact, efficient power transmission with high torque capacity and smooth operation in limited space, making it ideal for automatic transmissions and heavy machinery. Lay shafts provide a simpler, cost-effective solution for transferring power in manual transmissions, offering straightforward gear arrangements but with less compactness and flexibility compared to planetary systems. Your choice depends on the need for compact design and torque versus simplicity and cost-efficiency.

Table of Comparison

| Transmission Type | Planetary Gearset | Lay Shaft |

|---|---|---|

| Design | Central sun gear, planet gears, and ring gear | Parallel shaft with gears mounted on lay shaft |

| Size | Compact and lightweight | Bulkier and heavier |

| Efficiency | High power density, efficient torque transfer | Moderate efficiency due to gear mesh losses |

| Gear Shifting | Smoother, seamless shifting with fewer components | More mechanical complexity, less smooth shifts |

| Applications | Automatic transmissions, hybrid vehicles | Manual transmissions, older vehicle models |

| Durability | Long-lasting under high load conditions | Subject to wear due to multiple gear engagements |

| Cost | Higher manufacturing cost | Lower production cost |

Introduction to Planetary Gearsets and Lay Shafts

Planetary gearsets consist of a central sun gear, multiple planet gears, and a ring gear, enabling compact design and high torque transmission in automotive and industrial applications. Lay shafts, positioned parallel to the main shaft, serve as intermediary gears that transfer power within traditional manual transmissions, offering simplicity and ease of maintenance. The distinct configurations of planetary gearsets and lay shafts influence their efficiency, load distribution, and suitability for varying mechanical systems.

Core Components and Design Differences

Planetary gearsets consist of a central sun gear, multiple planet gears mounted on a carrier, and an outer ring gear, enabling compact design and high torque transmission with balanced load distribution. Lay shafts feature a main shaft with gears meshed directly to countershafts, providing straightforward power transfer but typically larger size and lower efficiency compared to planetary systems. The core difference lies in planetary gearsets' coaxial arrangement allowing multi-directional power flow, while lay shafts use parallel shafts, influencing overall gearbox design and performance characteristics.

Working Principles of Planetary Gearsets

Planetary gearsets operate through a central sun gear meshing with multiple planet gears, which revolve around it and engage with an outer ring gear, distributing torque evenly and enabling compact, efficient power transmission. This configuration allows for high torque density and smooth speed variation by altering the relative speed between the sun, planet carrier, and ring gear. The automatic load sharing among planet gears reduces wear and increases the gearset's durability compared to lay shaft systems that typically rely on fixed parallel shafts for torque transmission.

Operating Mechanism of Lay Shafts

Lay shafts operate by transferring rotational power through a series of fixed gears mounted on a secondary shaft parallel to the main shaft, enabling gear ratio changes without altering the input speed. Unlike planetary gearsets that use multiple planet gears revolving around a sun gear within a ring gear to distribute torque, lay shafts rely on direct gear meshing for power transmission. This mechanism allows for simpler construction and effective torque transfer in manual transmissions and some power tools.

Efficiency and Power Transmission Comparison

Planetary gearsets deliver higher efficiency and superior power transmission due to their compact design, multiple gear engagements, and balanced load distribution, resulting in reduced energy losses and enhanced torque capacity. Lay shafts, while simpler and cost-effective, exhibit lower efficiency because of higher friction and less optimal load distribution during power transmission. The planetary system's ability to handle greater power density makes it preferable for applications demanding robust efficiency and mechanical performance.

Space and Weight Considerations

Planetary gearsets offer a compact design by arranging gears concentrically, significantly reducing space and weight compared to traditional lay shaft systems. The coaxial configuration allows for higher torque density and better load distribution within a smaller volume, ideal for applications requiring lightweight and space-efficient transmissions. In contrast, lay shaft gearboxes are bulkier due to their linear gear arrangement, resulting in increased size and weight for the same power output.

Durability and Maintenance Requirements

Planetary gearsets offer superior durability due to their balanced load distribution across multiple gears, reducing wear compared to lay shaft designs, which concentrate stress on fewer components. Maintenance requirements for planetary gearsets tend to be lower, as their enclosed design protects gears from contaminants and reduces the need for frequent lubrication. Conversely, lay shaft gear systems require more regular inspection and maintenance to address potential alignment issues and wear on exposed gears.

Applications in Automotive and Industrial Sectors

Planetary gearsets are extensively used in automatic transmissions and hybrid vehicle drivetrains due to their high torque density, compact size, and ability to provide multiple gear ratios efficiently. Lay shafts find applications in manual transmissions and industrial machinery where simpler design and ease of maintenance are prioritized, offering reliable power transfer at moderate speeds. Automotive sectors rely on planetary gearsets for smooth shifting and fuel efficiency, while industrial sectors often prefer lay shaft gears for cost-effective, rugged performance in conveyor systems and heavy equipment.

Cost Implications and Manufacturing Complexity

Planetary gearsets typically involve higher manufacturing complexity due to their intricate design, which requires precise machining and assembly of multiple gears, leading to increased production costs. Lay shaft systems are generally simpler and less expensive to produce, as they consist of fewer components and rely on straightforward gear arrangements. Cost implications favor lay shaft designs for budget-sensitive applications, while planetary gearsets justify their higher expense with compactness and superior torque distribution efficiency.

Future Trends in Gearset and Shaft Technologies

Future trends in planetary gearset and lay shaft technologies emphasize advanced materials such as lightweight composites and high-strength alloys to improve durability and efficiency. Integration of smart sensors and IoT-enabled monitoring systems facilitates real-time performance analysis and predictive maintenance, reducing downtime. Emerging manufacturing techniques like additive manufacturing enable complex geometries and customized designs, optimizing gear meshing and shaft alignment for enhanced power transmission.

caratoz.com

caratoz.com