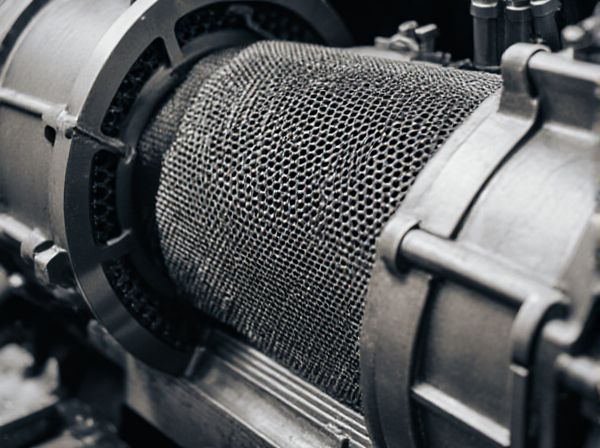

Photo illustration: Sliding mesh vs Constant mesh

Sliding mesh gearboxes offer variable gear engagement by physically sliding gears into mesh, providing smoother transitions and better control for Your vehicle. Constant mesh gearboxes keep all gears in constant contact, reducing wear and enhancing durability through synchronized shifting. Choosing between these systems depends on the desired balance between performance and maintenance requirements.

Table of Comparison

| Feature | Sliding Mesh Transmission | Constant Mesh Transmission |

|---|---|---|

| Gear Engagement | Direct sliding of gears on the shaft | Gears are always meshed; engagement by dog clutches |

| Gear Wear | High wear due to gear teeth sliding | Reduced wear; gears constantly engaged |

| Noise | High operational noise | Lower noise levels |

| Shifting Smoothness | Rough and difficult gear shifts | Smoother, easier gear changes |

| Complexity | Simple design | More complex mechanism |

| Durability | Less durable due to gear wear | More durable with longer lifespan |

| Typical Use | Used in older vehicles and tractors | Common in modern cars and commercial vehicles |

Introduction to Gear Transmission Systems

Gear transmission systems rely on the interaction of gears to transfer power efficiently between rotating shafts. Sliding mesh gears involve the axial movement of gears to engage and disengage, allowing variable gear ratios but requiring precise synchronization to prevent gear wear. Constant mesh gears maintain continuous engagement of all gear pairs, utilizing dog clutches to select gears smoothly, which enhances durability and operational reliability in vehicular and industrial applications.

Overview of Sliding Mesh Gearbox

The sliding mesh gearbox features gears that physically slide along the shaft to engage and disengage, allowing the driver to select different gear ratios manually. This design provides simple and direct mechanical connection but requires skillful operation to avoid gear clash. Unlike constant mesh gearboxes, where all gears remain in mesh and engagement occurs via dog clutches, sliding mesh gearboxes have fewer components but tend to cause more wear and noise during gear shifts.

Overview of Constant Mesh Gearbox

Constant mesh gearboxes feature gears that remain continuously engaged, ensuring smoother transitions and reducing wear by preventing gear teeth from clashing during shifts. This design improves durability and reliability compared to sliding mesh systems, where gears physically move to engage. Commonly used in motorcycles and manual transmissions, constant mesh gearboxes often employ dog clutches to synchronize gear engagement efficiently.

Key Differences Between Sliding Mesh and Constant Mesh

Sliding mesh transmissions allow gear changes by physically sliding gears along the shaft to engage different gear pairs, providing smoother shifting and better torque control. Constant mesh transmissions keep all gears meshed constantly, using dog clutches to engage the desired gear without sliding, resulting in faster shifts and reduced wear. The key difference lies in gear engagement--sliding mesh directly moves gears, while constant mesh uses synchronized gears to enhance durability and shift efficiency.

Working Principle of Sliding Mesh Gearbox

The sliding mesh gearbox operates by physically sliding gears along a shaft to engage and disengage different gear ratios, allowing smooth transmission of power between the engine and wheels. Unlike constant mesh gearboxes where all gears remain in mesh and dog clutches engage the desired gear, sliding mesh designs require the gears themselves to move into position. This mechanism provides direct mechanical connection but involves precise manual control to match gear speeds and avoid grinding during shifts.

Working Principle of Constant Mesh Gearbox

The working principle of a constant mesh gearbox involves all gears continuously meshing, with power transmission achieved by engaging dog clutches to select gears without disengaging the gears themselves. Unlike sliding mesh gearboxes, where gears physically slide to engage, constant mesh designs use fixed gears on parallel shafts that rotate constantly, enhancing smooth gear changes and reducing wear. This setup improves durability and operational efficiency by maintaining gear alignment and preventing gear grinding during shifts.

Advantages of Sliding Mesh Gearbox

Sliding mesh gearboxes offer precise control over gear engagement, allowing smooth shifting and reduced gear wear compared to constant mesh gearboxes. They enable direct meshing of gears, which improves power transmission efficiency and reduces energy losses in mechanical systems. The design simplicity of sliding mesh gearboxes also facilitates easier maintenance and repair, enhancing their operational lifespan in automotive and industrial applications.

Advantages of Constant Mesh Gearbox

Constant mesh gearboxes offer improved durability and smoother operation by keeping all gears continuously engaged, minimizing gear tooth wear and reducing the risk of gear damage compared to sliding mesh designs. The fixed gear engagement enables faster and more reliable shifting, enhancing overall transmission efficiency and vehicle performance. Maintenance requirements are lower due to decreased mechanical stress and fewer moving parts involved in gear changes.

Applications and Suitability

Sliding mesh gears are ideal for applications requiring variable speed and torque, such as automotive transmissions and heavy machinery, due to their ability to smoothly engage and disengage gears under load. Constant mesh gears are better suited for high-speed, consistent power transmission like in motorcycles and industrial equipment, providing durability and reduced wear through continuous gear engagement. Selection depends on operational conditions, with sliding mesh excelling in flexibility and constant mesh in efficiency and reliability.

Comparison Table: Sliding Mesh vs Constant Mesh

The Sliding Mesh gearbox provides smoother gear transitions by allowing gears to physically slide and mesh, resulting in less noise and wear compared to the Constant Mesh gearbox, where all gears are always in mesh with dog clutches used for gear selection. In terms of efficiency, Sliding Mesh gearboxes tend to have lower durability and require more maintenance, while Constant Mesh gearboxes offer higher reliability and are preferred for high-speed applications due to reduced gear engagement impact. Cost and complexity differ as Sliding Mesh gearboxes are simpler and cheaper but noisier, whereas Constant Mesh gearboxes involve more components and precision manufacturing, leading to higher initial costs but improved performance and longevity.

caratoz.com

caratoz.com