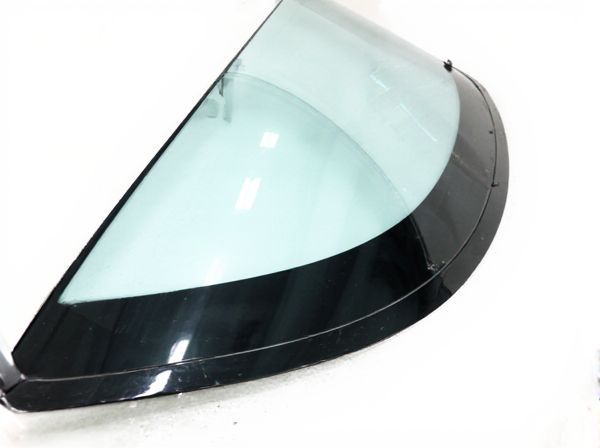

Photo illustration: Molding-Bonded vs Encapsulated

Molding-bonded components offer enhanced mechanical strength through a robust adhesive layer, ensuring durable bonding between parts. Encapsulated designs provide superior environmental protection by completely sealing components, safeguarding them against moisture, dust, and chemicals. Choosing between molding-bonded and encapsulated methods depends on your specific application's requirements for durability and environmental resistance.

Table of Comparison

| Feature | Molding-Bonded Windshield | Encapsulated Windshield |

|---|---|---|

| Installation | Uses rubber molding bonded to glass, manually fitted. | Glass is sealed with a urethane adhesive, factory precision. |

| Durability | Moderate resistance; molding can degrade over time. | High durability; urethane provides strong, lasting seal. |

| Waterproofing | Dependent on molding integrity; prone to leaks. | Excellent waterproofing due to full encapsulation. |

| Safety | Less secure bond; potential airbag deployment concerns. | Stronger bond improves structural integrity and safety. |

| Replacement Cost | Generally lower cost, less labor intensive. | Higher cost due to materials and precise installation. |

| Common Usage | Older vehicles and budget repairs. | Modern vehicles and OEM factory standards. |

Understanding Molding-Bonded and Encapsulated Technologies

Molding-bonded technology involves embedding electronic components within a molded resin, providing enhanced mechanical strength and environmental protection against moisture and dust. Encapsulated technology, on the other hand, uses a layer of protective encapsulant material to cover components, offering effective insulation and thermal management while maintaining design flexibility. Both methods improve device reliability but differ in application based on durability requirements and production complexity.

Key Differences Between Molding-Bonded and Encapsulated

Molding-bonded components feature a thermoset resin pressed directly onto the substrate, providing mechanical stability and thermal management, while encapsulated parts are enclosed in a protective shell for enhanced environmental resistance. Molding-bonded designs offer superior heat dissipation and mechanical strength, making them ideal for high-power applications, whereas encapsulated devices prioritize moisture, dust, and corrosion protection. The key difference lies in the interaction with the environment: molding-bonded provides structural integration, whereas encapsulation emphasizes sealing and external durability.

Material Selection in Molding-Bonded vs Encapsulated

Material selection in molding-bonded processes emphasizes compatibility between substrates and adhesives to ensure strong bonds and mechanical integrity, often requiring thermoset resins like epoxy or polyurethane. Encapsulated components utilize materials that provide environmental protection and electrical insulation, with silicone, epoxy, and polyurethane resins chosen for their moisture resistance and thermal stability. Selecting appropriate materials directly impacts durability, performance under stress, and environmental resistance in both molding-bonded and encapsulated assemblies.

Process Overview: Molding-Bonded vs Encapsulation

Molding-bonded processes integrate components by embedding them directly into a molded compound, ensuring strong mechanical adhesion and electrical insulation. Encapsulation surrounds the entire assembly with a protective material, providing enhanced protection against environmental factors such as moisture, dust, and vibration. Both techniques optimize device durability but differ in application flexibility and protective performance.

Performance and Reliability Comparison

Molding-bonded electronics provide superior mechanical strength and thermal stability by securely integrating components within a molded resin, enhancing performance under high-stress conditions. Encapsulated devices excel in environmental protection, offering enhanced moisture resistance and electrical insulation that improves reliability in harsh or corrosive environments. Performance-wise, molding-bonded solutions typically deliver better heat dissipation and structural integrity, while encapsulated designs prioritize prolonged device lifespan and protection against contamination.

Cost Implications of Each Method

Molding-bonded components typically offer lower upfront costs due to simpler manufacturing processes and less material usage compared to encapsulated counterparts. Encapsulation involves additional steps and materials for sealing and protection, which increases production expenses but enhances durability and environmental resistance. Businesses must weigh initial investment against long-term maintenance and reliability, as molding-bonded may require more frequent repairs while encapsulated designs often reduce lifecycle costs.

Applications and Use Cases

Molding-bonded components are primarily used in applications requiring high mechanical strength and environmental protection, such as automotive sensors and industrial connectors. Encapsulated devices excel in electronics and telecommunications, providing insulation and protection against moisture, dust, and vibrations. Both methods are crucial in aerospace and medical fields, where durability and reliability under extreme conditions are paramount.

Advantages of Molding-Bonded Packaging

Molding-bonded packaging offers superior mechanical stability and enhanced protection against moisture and contaminants compared to encapsulated packaging. This method ensures precise alignment and robust adhesion between components, improving thermal conductivity and electrical performance. The integration of molding materials reduces assembly complexity, leading to cost-effective manufacturing and increased device reliability.

Benefits of Encapsulated Solutions

Encapsulated solutions provide superior protection against moisture, dust, and mechanical stress compared to molding-bonded components, enhancing durability and reliability in harsh environments. These solutions offer improved thermal management due to better material integration, resulting in longer service life for electronic devices. Encapsulation also enables greater design flexibility, allowing for complex geometries and customized forms that optimize performance and assembly efficiency.

Choosing the Right Technology for Your Project

Choosing between molding-bonded and encapsulated technologies depends on the specific environmental protection and mechanical strength requirements of your project. Molding-bonded offers superior structural integrity and moisture resistance, ideal for harsh industrial applications, while encapsulated systems provide enhanced electrical insulation and ease of maintenance in sensitive electronic devices. Assessing factors like thermal conductivity, chemical exposure, and long-term durability will guide selecting the optimal solution for performance and cost-efficiency.

caratoz.com

caratoz.com