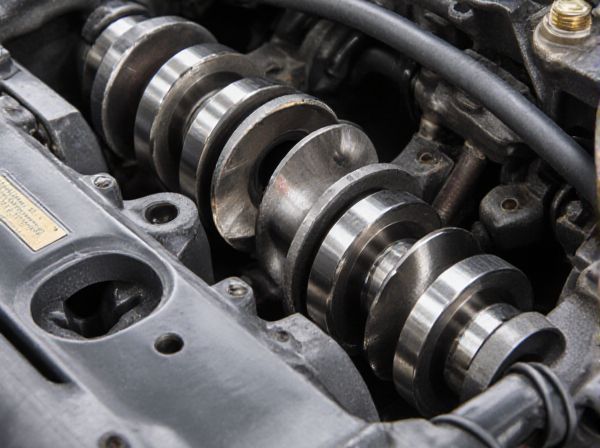

Photo illustration: External Balanced vs Internal Balanced Crankshaft

External balanced crankshafts use weights added outside the crankshaft to counteract engine vibrations, improving smoothness without modifying the crankshaft itself. Internal balanced crankshafts have built-in counterweights machined directly into the crankshaft, offering precise balance and reducing the need for external components. Your choice depends on engine design and performance requirements, with internal balancing often preferred for high-performance applications due to its accuracy.

Table of Comparison

| Feature | External Balanced Crankshaft | Internal Balanced Crankshaft |

|---|---|---|

| Balance Mechanism | Balance weights attached outside the crankshaft | Balance weights integrated within the crankshaft |

| Vibration | Higher vibration levels at high RPMs | Smoother operation with reduced vibrations |

| Weight Distribution | Uneven due to external weights | Even, optimized weight distribution |

| Durability | Potential for external damage to weights | Improved durability with enclosed balance weights |

| Manufacturing Complexity | Simpler, less costly production | More complex, higher manufacturing cost |

| Common Applications | Older and budget engines | Modern and performance engines |

Introduction to Crankshaft Balancing

Crankshaft balancing is critical for engine performance and durability, focusing on reducing vibrations caused by rotating and reciprocating masses. External balanced crankshafts use additional weights on the flywheel or harmonic balancer to counteract imbalance, while internal balanced crankshafts incorporate counterweights directly into the crankshaft design for improved precision and smoother operation. Proper crankshaft balancing enhances engine longevity, reduces bearing wear, and improves overall efficiency.

What Is an External Balanced Crankshaft?

An external balanced crankshaft uses additional weights or counterweights placed outside the crankshaft to achieve balance, improving engine smoothness and reducing vibration. This method contrasts with internal balancing, where weights are integrated within the crankshaft itself. External balancing is typically used in engines with heavy rotating components or aftermarket performance modifications to enhance stability and durability.

What Is an Internal Balanced Crankshaft?

An internal balanced crankshaft achieves rotational equilibrium through counterweights integrated within the crankshaft itself, eliminating the need for external weights on the harmonic balancer or flywheel. This design enhances engine smoothness by precisely counteracting reciprocating forces, reducing vibration and wear on engine components. Internal balancing is commonly preferred in high-performance and racing engines for its improved reliability and simplified assembly.

Key Differences Between External and Internal Balancing

External balanced crankshafts utilize counterweights mounted outside the crankshaft structure to offset engine vibrations, improving smoothness without modifying internal components. Internal balanced crankshafts achieve balance through precisely machined counterweights integrated within the crankshaft, enhancing durability and minimizing the need for additional external parts. The key difference lies in the placement of balancing weights, which affects the engine's overall performance, maintenance, and design complexity.

Pros and Cons of External Balanced Crankshafts

External balanced crankshafts provide precise counterbalance by using weights placed outside the crankshaft, enhancing engine stability and reducing vibration at high RPMs. They simplify balancing adjustments during engine assembly and repair, making them ideal for performance applications and custom setups. However, external balancing requires additional components like balance shafts or external weights, increasing complexity and potential maintenance compared to internal balanced crankshafts.

Pros and Cons of Internal Balanced Crankshafts

Internal balanced crankshafts offer improved engine vibration control by balancing mass within the crankshaft itself, leading to smoother operation and enhanced durability. They reduce the need for heavy external counterweights, which can decrease overall engine weight and improve response. However, internal balancing complicates manufacturing, increases production costs, and can limit design flexibility compared to external balanced crankshafts.

Performance Considerations for Engine Builders

External balanced crankshafts use added weights on the harmonic balancer or flywheel to counteract vibrations, facilitating easier balancing adjustments for engine builders, which improves overall engine smoothness. Internal balanced crankshafts integrate counterweights directly into the crankshaft design, offering a more streamlined configuration that reduces rotating mass and enhances high-RPM stability. Engine builders prioritize internal balancing for performance engines requiring precise rotational balance and reduced parasitic losses, while external balancing remains practical for retrofit or modular applications.

Cost Implications: Internal vs External Balancing

Internal balanced crankshafts typically incur higher manufacturing costs due to the precision machining required inside the crankshaft to achieve balance. External balanced crankshafts, by contrast, allow for balance adjustments via added weights on the flywheel or harmonic balancer, reducing machining complexity and lowering production expenses. Cost savings with external balancing make it a preferred choice for mass-produced engines, whereas internal balancing suits high-performance or custom applications despite its premium price.

Application Suitability: Choosing the Right Balance Type

External balanced crankshafts are ideal for high-performance engines requiring precise tuning of rotating assembly mass distribution, commonly found in racing and aftermarket applications. Internal balanced crankshafts suit mass-produced engines where ease of manufacturing and maintenance are prioritized, as the counterweights are integrated within the crankshaft itself. Selecting the right balance type depends on application demands, with external balance offering customization for power output and internal balance providing durability and simplicity for general use.

Conclusion: Which Crankshaft Balancing Method Is Best?

External balanced crankshafts are ideal for engines where precise weight distribution can be managed using external weights, improving overall engine smoothness and longevity. Internal balanced crankshafts, with integrated counterweights, offer a compact design and reduced rotational mass, enhancing engine efficiency and reliability without requiring additional components. The best method depends on the engine design and application, but internal balancing is often preferred for modern performance engines due to its simplicity and effective vibration reduction.

caratoz.com

caratoz.com