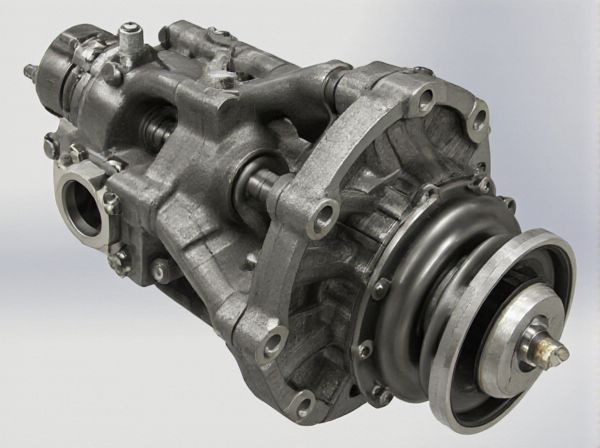

Photo illustration: Torsen Differential vs Gleason Differential

Torsen differentials provide smooth torque distribution by using helical gears, enhancing traction and vehicle stability in various driving conditions. Gleason differentials rely on hypoid gears, offering durability and efficient power transfer in heavy-duty applications. Understanding the differences helps you choose the right differential for your specific performance and handling needs.

Table of Comparison

| Feature | Torsen Differential | Gleason Differential |

|---|---|---|

| Type | Torque-Sensing Limited Slip | Spiral Bevel Gear Open or Limited Slip |

| Mechanism | Helical Gears providing automatic torque distribution | Bevel Gears with side gears and pinions |

| Torque Bias Ratio | Higher (typically 3:1 to 6:1), improves traction | Lower, depends on design and application |

| Slip Behavior | Limited slip, reduces wheel spin | Open differential allows wheel slip unless modified |

| Durability | Robust, suited for performance vehicles | Durable but less complex, common in standard vehicles |

| Maintenance | Requires specific lubrication, moderate maintenance | Simple design, easier maintenance |

| Typical Use | Sports cars, off-road, high-performance applications | Passenger cars, trucks, basic off-road use |

| Cost | Higher initial cost | Lower cost, widely used |

Introduction to Differential Systems

Torsen differentials utilize helical gears to provide continuous torque sensing and distribution, enhancing traction by automatically transferring power to the wheel with the most grip. Gleason differentials employ bevel gears with a traditional open or limited-slip design, balancing torque while allowing differential wheel speeds during cornering. Differential systems play a crucial role in vehicle stability and performance by managing power delivery and improving handling in various driving conditions.

What is a Torsen Differential?

A Torsen differential, short for Torque-Sensing differential, uses helical gears to distribute torque between wheels based on traction conditions, enhancing vehicle stability and handling. Unlike the Gleason differential, which typically utilizes traditional bevel gears, the Torsen design provides continuous torque biasing without the need for electronic controls or clutches. This mechanical efficiency makes Torsen differentials ideal for performance and off-road vehicles requiring reliable traction management.

What is a Gleason Differential?

A Gleason differential, also known as a hypoid differential, utilizes hypoid gears to transfer torque between the drive shaft and the wheels, offering smooth and quiet operation. This differential style is characterized by its ability to handle high torque loads and provides a compact design suitable for rear-wheel-drive vehicles. Unlike a Torsen differential, which uses worm and spur gears for torque-sensing, the Gleason differential emphasizes durability and noise reduction in automotive applications.

Key Mechanical Differences

The Torsen differential uses helical gears to provide torque-sensing capabilities that distribute power based on traction conditions, enabling smooth and continuous torque transfer between wheels. In contrast, the Gleason differential relies on straight spiral bevel gears and functions primarily as an open differential without inherent torque biasing, making it suitable for basic power distribution without traction enhancement. Key mechanical differences include the Torsen's ability to perform torque vectoring through its worm gears and the Gleason's traditional gear layout that prioritizes simplicity over traction control.

Torque Distribution Mechanisms

Torsen differentials utilize a system of helical gears that allow torque to be distributed variably between wheels based on traction, providing smooth and automatic torque transfer without slippage. Gleason differentials rely on a set of bevel gears, distributing torque more evenly but lacking the torque biasing capability of Torsen designs. The Torsen's gear geometry directly influences its torque bias ratio, optimizing traction in dynamic driving conditions, whereas Gleason differentials primarily serve as standard open differentials with fixed torque split.

Performance in Various Driving Conditions

Torsen differentials deliver superior torque distribution and enhanced traction on varied road surfaces thanks to their worm-gear design, allowing for smooth power transfer during cornering and low-traction conditions. Gleason differentials, typically found in limited-slip systems, offer reliable performance with predictable torque biasing but may experience less effective torque modulation in extreme off-road or high-performance scenarios. Vehicles equipped with Torsen differentials excel in dynamic driving environments, such as wet, snowy, or uneven terrains, where consistent grip and handling precision are critical.

Durability and Maintenance Requirements

Torsen differentials offer superior durability due to their helical gear design, which provides smooth torque transfer and withstands high torque loads with minimal wear. Gleason differentials, typically found in open or limited-slip applications, require more frequent maintenance as their bevel gears are more susceptible to wear and require precise lubrication. Maintenance demands for Torsen differentials are generally lower, with longer service intervals and less frequent adjustments compared to Gleason differentials, making them ideal for high-performance or off-road vehicles.

Common Applications and Vehicle Types

Torsen differentials are commonly used in high-performance sports cars, off-road vehicles, and all-wheel-drive systems due to their smooth torque distribution and superior traction on varying surfaces. Gleason differentials are often found in heavy-duty trucks, commercial vehicles, and some rear-wheel-drive cars because of their robust design and ability to handle high torque loads. Both differentials enhance vehicle stability and drivability, but Torsen excels in dynamic traction control while Gleason offers durability in demanding applications.

Pros and Cons of Torsen vs Gleason Differentials

Torsen differentials offer superior torque biasing with smooth, immediate power transfer to the wheel with the most traction, providing excellent handling and performance in high-demand conditions, but they tend to be heavier and more complex mechanically than Gleason differentials. Gleason differentials excel in durability and simplicity due to their spiral bevel gears, making them easier to manufacture and maintain, yet they lack the advanced torque sensing capabilities of Torsen units and may provide less responsive traction control. While Torsen differentials enhance vehicle stability and cornering, their higher cost and sensitivity to lubricant condition are potential drawbacks compared to the more robust and cost-effective Gleason design.

Which Differential is Best for Your Needs?

Choosing between a Torsen differential and a Gleason differential depends on your vehicle's performance requirements and driving conditions. The Torsen differential offers superior torque-sensing capabilities and smooth power distribution, ideal for off-road and high-performance applications. In contrast, the Gleason differential provides durability and simpler mechanics, making it suitable for heavy-duty or industrial vehicles where reliability under constant load is critical.

caratoz.com

caratoz.com