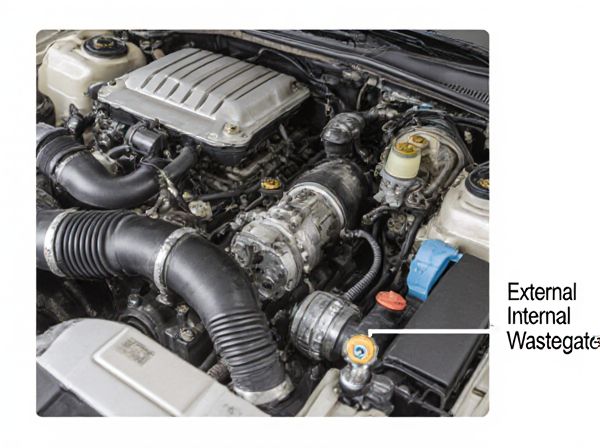

Photo illustration: External Wastegate vs Internal Wastegate

An external wastegate offers precise control over boost pressure by diverting exhaust gases away from the turbocharger turbine, improving performance and preventing over-boost. Internal wastegates are integrated into the turbocharger unit, simplifying installation but offering less flexibility and potentially less efficient boost control. Understanding your vehicle's needs will help you decide between the more customizable external wastegate and the compact internal wastegate.

Table of Comparison

| Feature | External Wastegate | Internal Wastegate |

|---|---|---|

| Design | Separate valve outside the turbocharger | Integrated valve inside the turbocharger housing |

| Boost Control | Precise and adjustable boost pressure regulation | Less precise, limited adjustment range |

| Heat Management | Better heat dissipation, cooler operation | Retains more heat due to internal placement |

| Complexity | More complex installation with additional piping | Simpler, compact setup |

| Cost | Higher cost due to extra components | Lower cost, factory integrated |

| Performance | Improved turbo response and higher boost capability | Standard performance, suitable for mild tuning |

Introduction to Wastegates: External vs Internal

External wastegates and internal wastegates both regulate exhaust gas flow to control turbocharger boost pressure, but they differ in design and performance. Internal wastegates are integrated into the turbocharger housing, offering compactness and simplicity, while external wastegates are separate units providing superior boost control and higher flow capacity. Understanding these differences helps optimize turbo system efficiency and engine performance.

How Turbo Wastegates Work

Turbo wastegates regulate exhaust gas flow to control turbine speed and prevent overboost by diverting excess exhaust gases away from the turbine wheel. Internal wastegates are integrated within the turbocharger housing, offering compact design and faster response, while external wastegates are separate units providing more precise boost control and higher capacity for large or high-performance engines. Both systems rely on a pressure actuator that opens the wastegate flap when the desired boost pressure is reached, ensuring optimal turbine efficiency and protecting engine components.

External Wastegate: Features and Function

External wastegates offer superior boost control by diverting exhaust gases away from the turbocharger turbine, preventing overboost and reducing turbo lag. Their separate housing allows for larger valve sizes and better heat dissipation compared to internal wastegates, which are integrated into the turbocharger. This design enhances durability and tuning precision, making external wastegates ideal for high-performance and heavily modified engines.

Internal Wastegate: Features and Function

Internal wastegates feature an integrated valve within the turbocharger housing that regulates exhaust gas flow to control boost pressure, enhancing engine efficiency and preventing overboost conditions. Their compact design simplifies installation and reduces weight compared to external wastegates, making them suitable for OEM turbocharged engines. Internal wastegates provide reliable boost control but typically offer less flexibility and tuning potential than external wastegates, which are separate components allowing for custom setups.

Performance Differences Between External and Internal Wastegates

External wastegates generally provide superior boost control by allowing more precise regulation of exhaust flow, leading to quicker spool times and higher boost pressures compared to internal wastegates. Internal wastegates, integrated into the turbo housing, offer simplicity and lower cost but often suffer from higher backpressure and less consistent boost control, which can limit peak performance. Vehicles tuned for maximum power output and responsiveness typically benefit from external wastegates due to their enhanced durability and ability to handle increased exhaust gas volume efficiently.

Cost Comparison: External vs Internal Wastegates

External wastegates typically cost more due to their separate, sturdier housing and enhanced control over exhaust flow, which improves turbo system efficiency. Internal wastegates, integrated into the turbocharger, are generally more affordable and simpler to install but may offer less precise boost regulation. The price difference often reflects the trade-off between external wastegate durability and performance versus internal wastegate cost-effectiveness and convenience.

Installation Considerations for Each Wastegate Type

External wastegates require more complex installation involving additional piping and mounting brackets, providing greater flexibility in placement and superior control over exhaust flow and boost pressure. Internal wastegates are integrated into the turbocharger housing, simplifying installation with fewer components and a compact setup but offer limited tuning potential and less efficient boost control. Proper routing of the external wastegate's dump tube is crucial to avoid heat damage, while internal wastegates rely on factory-designed pathways, reducing potential installation errors.

Tuning and Boost Control: External vs Internal Wastegates

External wastegates provide superior tuning flexibility and precise boost control by allowing independent routing of exhaust gases, enabling quicker spool time and more stable boost under high-performance conditions. Internal wastegates are integrated into the turbocharger, limiting tuning options and often resulting in less accurate boost control due to shared exhaust paths and potential heat buildup. For advanced tuning and aggressive boost strategies, external wastegates are preferred, while internal wastegates suit moderate boost levels and simpler setups.

Applications: Which Wastegate Is Best for Your Build?

External wastegates offer precise boost control and are ideal for high-performance applications and heavily modified engines due to their ability to handle higher exhaust flow and reduce turbo lag. Internal wastegates, embedded within the turbocharger housing, provide a simpler and more cost-effective solution for stock or mildly tuned engines with moderate boost pressures. Choosing the best wastegate depends on your build's power goals and tuning complexity, with external wastegates favored for aggressive setups and internal wastegates suitable for everyday street performance.

Conclusion: Choosing the Right Wastegate for Optimal Turbo Performance

External wastegates provide superior boost control and are ideal for high-performance turbo applications due to their ability to handle higher exhaust flow and reduce turbo lag. Internal wastegates offer simplicity and cost-effectiveness, making them suitable for stock or mildly modified engines with moderate boost levels. Selecting the right wastegate depends on the turbo system's boost requirements, vehicle use, and desired performance gains.

caratoz.com

caratoz.com