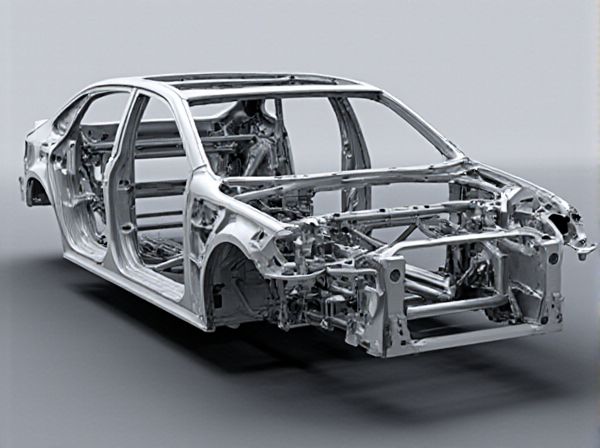

Photo illustration: Tubular Frame vs Monocoque Frame

Tubular frames consist of a network of steel or aluminum tubes welded together, offering durability and ease of repair, making them ideal for heavy-duty or custom-built vehicles. Monocoque frames integrate the body and chassis into a single shell, enhancing structural rigidity and reducing overall weight, which improves fuel efficiency and handling. Your choice depends on whether you prioritize strength and repairability or lightweight performance and modern design.

Table of Comparison

| Feature | Tubular Frame | Monocoque Frame |

|---|---|---|

| Construction | Welded metal tubes forming a rigid framework | Single shell body structure distributing stress |

| Weight | Relatively heavier due to reinforced tubes | Lighter, optimized for weight efficiency |

| Strength | High rigidity and impact resistance | Excellent strength with integrated load distribution |

| Manufacturing Cost | Lower cost, simpler fabrication | Higher cost due to complex molding and materials |

| Repair & Maintenance | Easier to repair damaged sections | Challenging repairs, often requires panel replacement |

| Application | Common in racing and custom cars | Standard in modern passenger vehicles |

Introduction to Motorcycle Frame Types

Tubular frames, constructed from interconnected steel or aluminum tubes, offer flexibility and ease of repair, making them ideal for off-road and custom motorcycles. Monocoque frames integrate the body and chassis into a single structure, enhancing rigidity and reducing weight, commonly seen in high-performance and racing motorcycles. Understanding these frame types highlights their impact on handling, durability, and overall motorcycle design.

What is a Tubular Frame?

A tubular frame consists of numerous steel or aluminum tubes welded together to form a strong, lightweight structure commonly used in motorcycles and bicycles. This frame type offers excellent rigidity and ease of repair due to its separate connected tubes, making it ideal for off-road and high-performance applications. Compared to monocoque frames, tubular frames provide greater flexibility in design modifications and better absorption of impact forces.

What is a Monocoque Frame?

A monocoque frame is a structural design where the external skin supports most of the load, eliminating the need for an internal frame. This design enhances rigidity and reduces weight by integrating the body and chassis into a single cohesive unit. Commonly used in modern automotive and aerospace engineering, monocoque frames provide improved performance and safety compared to traditional tubular frames.

Structural Differences Between Tubular and Monocoque Frames

Tubular frames consist of multiple welded tubes that form a skeleton, providing rigidity through interconnected joints and allowing for easy repair and customization. Monocoque frames integrate the body and chassis into a single shell, distributing structural loads across the entire surface for enhanced strength and reduced weight. The tubular design excels in modularity and damage tolerance, while the monocoque structure offers improved aerodynamic efficiency and stiffness.

Weight Comparison: Tubular vs Monocoque Frames

Tubular frames generally weigh more due to their construction from multiple steel or aluminum tubes joined by lugs or welds, whereas monocoque frames utilize integrated composite materials like carbon fiber, optimizing strength-to-weight balance and reducing overall mass. The monocoque design allows for precise material distribution, minimizing excess weight without compromising structural integrity, making it significantly lighter than traditional tubular frames. Cyclists seeking performance advantages often prefer monocoque frames for their superior weight efficiency and stiffness-to-weight ratio.

Strength and Durability Analysis

Tubular frames offer enhanced strength due to their interconnected tube design that distributes stress evenly, providing superior resistance to impact and deformation. Monocoque frames integrate the body and chassis into a single unit, resulting in high rigidity and durability by efficiently managing load distribution and minimizing material fatigue. Strength analysis shows tubular frames excel in heavy-duty applications, while monocoque frames deliver optimal durability with lighter weight, supporting precise handling and long-term structural integrity.

Manufacturing Complexity and Cost

Tubular frames involve welding multiple metal tubes into a framework, resulting in higher manufacturing complexity due to precise joint alignment and labor-intensive assembly, which increases production costs. Monocoque frames use molded materials like carbon fiber or aluminum in a single shell structure, reducing complexity by eliminating multiple joints but requiring expensive molds and advanced manufacturing techniques that drive up initial tooling and material expenses. Cost efficiency in tubular frames arises from simpler materials but longer assembly, whereas monocoque frames balance high upfront costs with potential long-term savings through improved strength-to-weight ratios and aerodynamic advantages.

Impact on Ride Quality and Handling

Tubular frames, consisting of a network of metal tubes, offer enhanced flexibility that absorbs road vibrations, resulting in a smoother ride quality and improved handling on rough terrains. Monocoque frames, made from a single molded structure, provide higher rigidity and weight reduction, which translates to precise handling and better power transfer but may transmit more road shocks. The choice between tubular and monocoque frames directly affects ride comfort and vehicle responsiveness, with tubular frames favoring cushioning and monocoque frames optimizing stiffness and control.

Popular Motorcycle Models Using Each Frame Type

Popular motorcycles featuring tubular frames include the Royal Enfield Classic 350 and the Harley-Davidson Iron 883, which utilize steel tubular frames for enhanced durability and ease of customization. In contrast, models like the Honda CBR600RR and Yamaha YZF-R1 employ monocoque frames, offering superior rigidity and weight reduction by integrating the frame and body into a single structural unit. The choice between tubular and monocoque frames significantly influences handling characteristics and maintenance complexity in these motorcycle categories.

Choosing the Right Frame for Your Riding Needs

Tubular frames offer enhanced strength and ease of repair, making them ideal for rugged off-road and touring bikes requiring durability and customization. Monocoque frames, constructed as a single molded piece, provide superior aerodynamics and lighter weight, benefiting road cyclists and racers prioritizing speed and efficiency. Selecting the right frame depends on your riding style, terrain, and performance goals, with tubular frames suited for versatility and monocoque frames optimized for competitive riding.

caratoz.com

caratoz.com