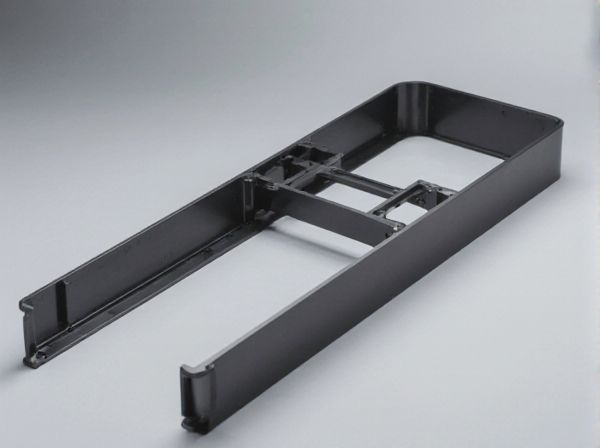

Photo illustration: Boxed Frame vs C-Channel Frame

A boxed frame offers enhanced structural rigidity and protection by fully enclosing the frame, making it ideal for heavy-duty applications and increased load-bearing capacity. A C-channel frame, featuring an open channel shape, provides easier access for mounting components and is often lighter, which suits applications where weight savings and flexibility are priorities. Your choice depends on the balance between strength requirements and the need for accessibility or weight considerations.

Table of Comparison

| Feature | Boxed Frame | C-Channel Frame |

|---|---|---|

| Structure | Closed rectangular steel tubes | Open C-shaped steel channels |

| Strength | High rigidity and torsional resistance | Moderate strength, less torsion resistance |

| Weight | Heavier due to enclosed design | Lighter, simpler construction |

| Durability | Resists bending and twisting better | More prone to deformation under stress |

| Manufacturing Cost | Higher production cost | Lower cost, easier fabrication |

| Use Case | Performance and heavy-duty vehicles | Economical and light vehicles |

Introduction to Trailer Frame Types

Trailer frame types mainly include Boxed Frame and C-Channel Frame, each offering distinct structural benefits. Boxed Frames provide enhanced strength and durability through their enclosed, rectangular design, making them ideal for heavy loads and rough terrain. In contrast, C-Channel Frames are lighter, easier to manufacture, and cost-effective, often used in lighter trailers requiring less rigidity.

Overview of Boxed Frame Construction

Boxed frame construction features a fully enclosed rectangular profile formed by welding four flat steel plates, enhancing torsional rigidity and load-bearing capacity compared to open profiles. This design provides superior resistance to bending and twisting under heavy loads, making it ideal for structural applications requiring high strength and durability. Commonly used in heavy machinery, trailers, and industrial frames, boxed frames deliver improved durability and stability in demanding environments.

Overview of C-Channel Frame Construction

C-channel frame construction utilizes a steel or aluminum profile shaped like the letter "C," providing excellent structural support with lightweight characteristics. The design allows easy attachment points for panels, wiring, and other components, making it ideal for modular and customizable assemblies. These frames offer superior load distribution and resistance to bending compared to boxed frames, enhancing durability in industrial and construction applications.

Strength and Durability Comparison

Boxed frames offer superior strength and durability due to their closed rectangular design, which evenly distributes load and resists torsional forces. In contrast, C-channel frames, featuring an open-section profile, are more prone to twisting and bending under heavy stress, reducing their overall durability. Engineering applications requiring high structural integrity and resistance to deformation typically favor boxed frames for enhanced performance and longevity.

Weight and Payload Capacity Differences

Boxed frames offer greater structural rigidity and higher payload capacity due to their fully enclosed design, distributing stress evenly across the frame. C-channel frames are lighter because of their open, U-shaped cross-section but typically support lower payloads and are more susceptible to twisting under heavy loads. Choosing between the two depends on the trade-off between weight savings and the need for higher load-bearing strength in truck chassis design.

Cost Considerations: Boxed vs C-Channel

Boxed frames typically entail higher material and fabrication costs due to their enclosed design, offering superior strength and durability for heavy-duty applications. C-channel frames are more cost-effective with simpler, open-profile construction, making them ideal for lighter loads and budget-sensitive projects. Evaluating project requirements ensures selecting between boxed frames for long-term investment or C-channel frames for immediate cost savings.

Corrosion Resistance and Maintenance

Boxed frame structures typically offer superior corrosion resistance due to their enclosed design that limits exposure to moisture and contaminants, reducing the risk of rust formation compared to open C-channel frames. C-channel frames require more frequent maintenance, including inspections and protective coatings, since their open profile exposes more surface area to corrosive elements such as water and chemicals. Proper surface treatment like galvanization or powder coating is essential for both frame types to enhance durability and minimize long-term maintenance costs.

Best Use Cases for Boxed Frames

Boxed frames excel in heavy-duty structural applications requiring maximum strength and rigidity, such as in commercial vehicles, trailers, and heavy equipment chassis where load distribution and torsional resistance are critical. They are ideal for environments demanding resistance to bending and impact, providing enhanced durability over C-channel frames. Boxed frames also perform well in off-road and construction machinery due to their enclosed design that protects against corrosion and damage.

Best Use Cases for C-Channel Frames

C-channel frames excel in applications requiring lightweight support structures such as conveyor systems, shelving, and small machinery frames due to their ease of fabrication and cost-effectiveness. Their open profile allows for simple access to wiring and plumbing, making them ideal for construction and industrial environments where maintenance and modifications are frequent. C-channel frames provide efficient load distribution in scenarios with primarily bending or shear forces, especially in horizontal beams and support columns.

Choosing the Right Frame for Your Needs

When choosing the right frame for your needs, consider the structural strength and application environment of boxed frames versus C-channel frames. Boxed frames provide enhanced rigidity and torsional resistance, making them ideal for heavy loads and high-stress situations in construction and industrial settings. C-channel frames offer lighter weight and easier installation, suitable for projects with moderate load requirements and where cost-efficiency or flexibility is a priority.

caratoz.com

caratoz.com