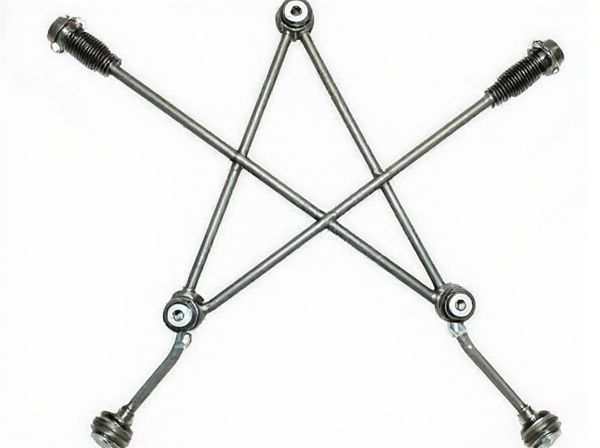

Photo illustration: Parallelogram Steering Linkage vs Triangular Steering Linkage

Parallelogram steering linkage offers smoother and more consistent steering control due to its parallel tie rod arrangement, which maintains tire alignment throughout the steering range. Triangular steering linkage, on the other hand, provides a more compact design and can absorb road shocks better but may sacrifice some precision in steering response. Choose the system that best matches your driving needs for optimized handling and vehicle stability.

Table of Comparison

| Feature | Parallelogram Steering Linkage | Triangular Steering Linkage |

|---|---|---|

| Design | Four-bar linkage forming a parallelogram shape | Three-bar linkage forming a triangular shape |

| Steering Precision | High accuracy and stable wheel alignment | Moderate accuracy with slight alignment variation |

| Complexity | More complex with additional links and joints | Simpler and fewer components |

| Durability | High durability under continuous steering load | Less durable due to fewer support points |

| Common Usage | Widely used in modern vehicles for precise control | Typically found in older or lightweight vehicle models |

| Maintenance | Requires regular inspection of multiple joints | Lower maintenance due to simpler design |

| Cost | Higher manufacturing and maintenance cost | Lower cost, easier to produce |

Introduction to Steering Linkage Systems

Steering linkage systems are crucial components in vehicle mechanics, responsible for transmitting the driver's steering input to the wheels. Parallelogram steering linkage features a four-bar arrangement that maintains consistent wheel alignment, enhancing stability and driving precision. Triangular steering linkage, often used in older or specialized vehicles, employs a three-bar configuration, which can offer simpler construction but may sacrifice some control accuracy and durability.

Overview of Parallelogram Steering Linkage

Parallelogram steering linkage consists of two parallel arms connected to the steering knuckles and a center link, creating a geometric parallelogram that ensures smooth and precise wheel movement. This design maintains constant steering geometry angles, reducing tire wear and improving vehicle stability during turns. Commonly used in passenger cars and light trucks, it offers reliable performance and ease of maintenance compared to alternative linkage systems.

Key Features of Triangular Steering Linkage

The Triangular Steering Linkage features a three-point connection system that enhances stability and precise steering control by distributing forces evenly across its structure. Its geometric design improves durability and reduces play in the steering mechanism, offering better response and handling compared to the simpler Parallelogram Steering Linkage. This linkage type also facilitates smoother steering input transmission, minimizing wear on joints and extending the overall lifespan of the steering assembly.

Structural Differences Between Parallelogram and Triangular Linkages

Parallelogram steering linkages feature a symmetrical four-bar linkage configuration, ensuring uniform motion and consistent geometry throughout steering angles. Triangular steering linkages consist of a three-bar arrangement forming a rigid triangle, offering enhanced structural stiffness but reduced flexibility compared to parallelograms. These structural differences influence steering precision, with parallelograms providing smoother motion and triangular linkages delivering increased durability in heavy-duty applications.

Advantages of Parallelogram Steering Linkage

Parallelogram steering linkage offers superior stability and precise wheel alignment, enhancing vehicle control and safety compared to triangular steering linkage. It provides consistent steering geometry throughout suspension travel, reducing tire wear and improving handling. The design also simplifies maintenance and adjustments, making it more practical for automotive applications.

Benefits of Triangular Steering Linkage

Triangular steering linkage offers enhanced stability and precise steering control due to its rigid triangular geometry, reducing play and improving vehicle handling compared to parallelogram steering linkage. Its design minimizes angular deflections and distributes steering forces evenly, resulting in smoother and more responsive steering performance. This linkage also provides greater durability under high-stress conditions, making it ideal for heavy-duty or off-road applications.

Performance Comparison: Parallelogram vs Triangular Steering Linkage

Parallelogram steering linkages offer smoother, more consistent steering response due to equal-length arms maintaining constant track bar angles, which enhances vehicle stability during turns. Triangular steering linkages, with their shorter linkage arm, provide quicker steering feedback but can introduce slight inconsistencies at extreme angles, affecting precision under high-stress conditions. Overall, parallelogram setups excel in durability and repeatability, while triangular linkages prioritize rapid directional changes, influencing performance based on driving style and terrain.

Application Suitability: Which Vehicles Use Which System?

Parallelogram steering linkage is commonly used in passenger cars and light trucks due to its precise control and straightforward geometry, making it ideal for conventional front-wheel or rear-wheel steering setups. Triangular steering linkage, often found in heavy-duty trucks and off-road vehicles, provides enhanced stability and strength to withstand higher stress and rough terrain conditions. The choice between these systems depends on vehicle size, intended use, and required durability in steering performance.

Steering Response and Handling Characteristics

Parallelogram steering linkage offers precise steering response with minimal play, enhancing vehicle control and stability due to its consistent geometry during wheel movement. Triangular steering linkage provides improved handling characteristics by reducing bump steer and maintaining optimal toe settings throughout suspension travel, resulting in smoother, more predictable cornering. Both systems influence steering dynamics, but the parallelogram design excels in responsiveness, while the triangular setup prioritizes refined handling stability.

Maintenance and Longevity Considerations

Parallelogram steering linkages typically require more frequent maintenance due to multiple pivot points and bushings that are prone to wear, impacting their longevity. Triangular steering linkages and generally feature fewer moving parts and robust construction, resulting in lower maintenance needs and extended service life. Selecting a linkage system with durable materials and proper lubrication can significantly enhance longevity and reduce maintenance intervals.

caratoz.com

caratoz.com