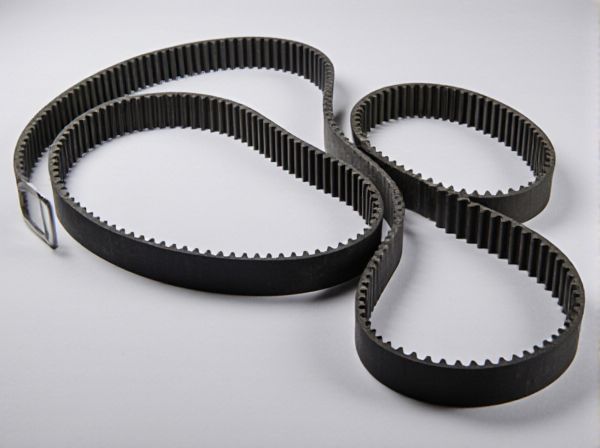

Photo illustration: Curvilinear Timing Belt vs Trapezoidal Timing Belt

Curvilinear timing belts offer smoother and quieter operation due to their rounded tooth profiles, reducing wear and extending belt life in high-precision applications. Trapezoidal timing belts feature a more traditional tooth shape that provides greater load-carrying capacity and are often preferred for heavy-duty machinery. Your choice depends on the specific requirements for noise reduction, durability, and load in your mechanical system.

Table of Comparison

| Feature | Curvilinear Timing Belt | Trapezoidal Timing Belt |

|---|---|---|

| Tooth Profile | Curved, rounded teeth for smooth engagement | Straight, trapezoidal-shaped teeth |

| Performance | Higher precision and less vibration | Good for moderate load applications |

| Durability | Longer lifespan due to reduced wear | Shorter lifespan, more wear under high stress |

| Noise Level | Quieter operation | Noisier due to tooth impact |

| Application | High-performance engines and precision timing | Standard engines with less demanding timing needs |

| Cost | Higher manufacturing cost | More cost-effective |

| Common Materials | Neoprene with fiberglass or steel cords | Rubber with polyester or Kevlar cords |

Introduction to Timing Belt Profiles

Timing belt profiles are essential in determining the belt's performance, with curvilinear and trapezoidal designs being the most common. Curvilinear timing belts feature rounded tooth profiles that offer smoother engagement and reduced stress on the belt, enhancing durability and quieter operation. In contrast, trapezoidal belts have more angular teeth, providing strong grip and efficient power transmission but may experience increased wear and noise over time.

What is a Curvilinear Timing Belt?

A Curvilinear Timing Belt features a unique tooth profile designed to provide smoother engagement with pulleys, reducing noise and vibration compared to conventional trapezoidal belts. Its curved teeth allow for increased load distribution and improved power transmission efficiency, making it ideal for high-performance applications. Unlike trapezoidal timing belts, curvilinear belts enable longer service life and enhanced precision in synchronous drive systems.

Understanding Trapezoidal Timing Belts

Trapezoidal timing belts feature teeth with a trapezoidal shape, offering reliable power transmission and resistance to slippage in various mechanical applications. Their design allows for efficient load distribution and is commonly used in automotive engines, industrial machinery, and 3D printers. Understanding the geometry and material composition of trapezoidal timing belts is crucial for optimizing belt tension, durability, and overall system performance in comparison to curvilinear timing belts.

Comparison of Tooth Profiles

Curvilinear timing belts feature rounded, curved tooth profiles that provide smoother engagement and reduced noise compared to trapezoidal timing belts with their triangular, sharp-edged teeth. The curved tooth design of curvilinear belts offers higher load capacity and better wear resistance, enhancing overall belt longevity. In contrast, trapezoidal belts exhibit higher backlash and increased stress concentration, which can lead to accelerated tooth wear and reduced precision in power transmission.

Performance and Efficiency Differences

Curvilinear timing belts offer improved load distribution and reduced backlash compared to trapezoidal timing belts, resulting in smoother and more precise motion control. The enhanced tooth engagement of curvilinear belts increases efficiency by minimizing slippage and wear, which extends the lifespan of the belt system. Trapezoidal belts, while typically simpler and more cost-effective, tend to exhibit higher noise levels and lower energy efficiency due to their less optimized tooth profile.

Load Capacity and Durability

Curvilinear timing belts feature a load capacity significantly higher than trapezoidal timing belts due to their continuous tooth profile, which allows for smoother power transmission and reduced stress concentration. The enhanced tooth engagement in curvilinear belts improves durability by minimizing wear and fatigue over prolonged use, making them suitable for high-torque applications. In contrast, trapezoidal timing belts tend to experience increased slippage and faster tooth wear under heavy loads, limiting their longevity and efficiency.

Noise and Vibration Characteristics

Curvilinear timing belts feature a more continuous tooth engagement that significantly reduces noise and vibration compared to trapezoidal timing belts, which have abrupt tooth contact leading to higher acoustic emissions. The smoother meshing pattern of curvilinear belts results in less dynamic tooth impact and lower amplitude vibrations, enhancing operational quietness. This makes curvilinear belts ideal for applications requiring minimal noise and precise motion control.

Application Suitability

Curvilinear timing belts excel in high-speed and high-torque applications due to their enhanced tooth engagement and reduced noise, making them ideal for precision machinery and automotive engines. Trapezoidal timing belts are more suited for lower-speed applications with moderate loads, commonly found in office equipment and simple conveyor systems. Selecting between these belts depends on the operational environment, load requirements, and desired lifespan, with curvilinear belts offering superior durability in demanding conditions.

Maintenance and Lifespan Considerations

Curvilinear timing belts offer enhanced durability and reduced wear due to their smoother tooth profile, resulting in longer maintenance intervals compared to trapezoidal timing belts. Trapezoidal belts, with their more aggressive tooth design, often require more frequent inspections and replacements to prevent premature failure. Proper tensioning and alignment are critical for both belt types, but curvilinear belts generally provide better longevity under high-load conditions, minimizing downtime and maintenance costs.

Choosing the Right Timing Belt for Your Needs

Curvilinear timing belts offer smoother power transmission and higher efficiency due to their rounded tooth profile, making them ideal for applications requiring reduced noise and precise timing. Trapezoidal timing belts, characterized by their robust, square-tooth design, provide strong grip and durability in heavy-load conditions but may generate more vibration. Selecting the right timing belt depends on factors like load capacity, desired noise level, and precision requirements, with curvilinear belts suited for high-speed machinery and trapezoidal belts preferred for high-torque, heavy-duty operations.

caratoz.com

caratoz.com