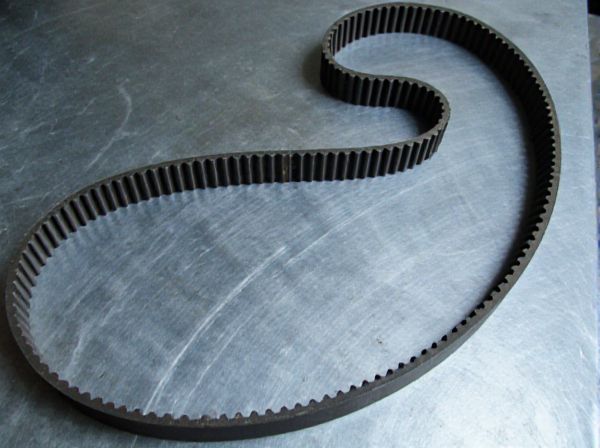

Photo illustration: Belt-in-Oil vs Conventional Timing Belt

Belt-in-oil timing systems offer superior durability and quieter operation compared to conventional timing belts due to their lubrication within the engine oil environment. Your engine benefits from reduced friction and enhanced longevity, as the belt is protected from external contaminants and heat. Conventional timing belts, although easier to replace and more cost-effective initially, require frequent inspection and replacement to prevent engine damage.

Table of Comparison

| Feature | Belt-in-Oil Timing Belt | Conventional Timing Belt |

|---|---|---|

| Design | Submerged in engine oil, continuous lubrication | Exposed to air, dry operation |

| Durability | High resistance to wear, lasts up to 100,000+ miles | Moderate durability, typical lifespan 60,000-90,000 miles |

| Maintenance | Minimal, oil quality crucial | Regular inspection and replacement required |

| Noise Level | Quieter operation due to oil lubrication | More noise from dry belt friction |

| Cost | Higher initial cost | Lower upfront cost |

| Application | Modern engines with integrated lubrication systems | Standard engines, widely used |

| Risk | Dependence on oil condition, risks if oil leaks | Risk of belt wear and snapping if neglected |

Introduction to Timing Belt Technologies

Timing belt technologies have evolved to include both conventional rubber belts and advanced belt-in-oil systems, each serving critical roles in engine timing and synchronization. Conventional timing belts are typically made of reinforced rubber and rely on dry operation, requiring periodic replacement to prevent wear and failure. Belt-in-oil technology immerses the timing belt in engine oil, enhancing durability, reducing friction, and enabling longer service intervals while maintaining precise timing control.

What is a Belt-in-Oil Timing Belt?

A Belt-in-Oil timing belt operates submerged in engine oil, enhancing durability and reducing friction compared to conventional dry timing belts. It benefits from continuous lubrication, leading to improved heat dissipation and extended service life, especially in high-performance engines. This design contrasts with traditional timing belts, which rely on external tensioners and lack oil immersion, often requiring more frequent maintenance.

What is a Conventional Timing Belt?

A conventional timing belt is a rubber belt with internal fibers designed to synchronize the rotation of the crankshaft and camshaft in an internal combustion engine, ensuring precise valve timing. It operates outside the engine's oil environment, requiring regular inspection and replacement to prevent wear and potential engine damage. Conventional timing belts are cost-effective but typically have a shorter lifespan compared to belt-in-oil systems, which run immersed in engine oil for improved durability.

Design Differences: Belt-in-Oil vs Conventional Belts

Belt-in-oil timing belts are designed with special materials and coatings that allow continuous lubrication within the engine oil, enhancing durability and reducing friction, whereas conventional timing belts operate dry and rely on external tensioners for proper function. Belt-in-oil systems often feature a more compact, flexible belt structure that withstands constant immersion in oil without degradation, while conventional belts use reinforced rubber composites optimized for dry conditions. The design differences result in varied maintenance intervals and performance characteristics, with belt-in-oil belts providing increased lifespan and improved resistance to heat and wear compared to conventional timing belts.

Performance Comparison: Efficiency and Durability

Belt-in-oil timing belts demonstrate superior efficiency by reducing friction and operating in a lubricated environment, leading to smoother engine performance and increased fuel economy. Their durability surpasses conventional dry timing belts due to enhanced resistance to wear, heat, and contamination, extending service intervals significantly. Conventional timing belts, while cost-effective, often require more frequent replacements and may suffer from greater wear in harsh conditions compared to belt-in-oil systems.

Maintenance Requirements and Lifespan

Belt-in-oil timing belts are designed for enhanced durability and require less frequent maintenance compared to conventional dry timing belts due to their continuous lubrication within the engine oil. The enclosed oil environment reduces friction and wear, extending the belt's lifespan typically up to 100,000 to 150,000 miles, whereas conventional belts often need replacement around 60,000 to 100,000 miles. Proper oil quality and regular engine oil changes are crucial for maintaining belt-in-oil performance, while conventional timing belts demand routine inspections for cracks, wear, and tension adjustments to prevent premature failure.

Noise, Vibration, and Harshness (NVH) Factors

Belt-in-oil timing belts offer superior noise, vibration, and harshness (NVH) reduction compared to conventional dry timing belts, as the oil lubrication dampens vibrations and minimizes friction-induced noise. The continuous oil bath environment lowers belt wear and enhances flexibility, resulting in smoother operation and less mechanical noise. Conventional timing belts, exposed to air, typically generate higher NVH levels due to increased belt tension and dry friction, leading to more audible vibrations and harsher engine feedback.

Cost Implications and Installation Considerations

Belt-in-Oil timing belts offer longer service life and reduced maintenance costs compared to conventional dry timing belts, but their initial replacement cost tends to be higher due to specialized materials and oil containment requirements. Installation of Belt-in-Oil systems demands precise handling and often professional expertise to prevent oil contamination and ensure proper belt tension, whereas conventional timing belts are generally easier and quicker to replace, leading to lower labor costs. Vehicle models equipped with Belt-in-Oil systems may experience fewer total ownership expenses over time despite the higher upfront costs, making the choice dependent on long-term maintenance planning.

Applications and Compatibility in Modern Engines

Belt-in-oil timing belts are specifically designed for modern engines requiring enhanced durability and quieter operation, especially in turbocharged and high-performance vehicles due to their continuous lubrication inside the oil bath. Conventional timing belts, typically made from reinforced rubber and positioned outside the engine oil environment, suit older or less demanding engines where ease of replacement and lower cost are priorities. Compatibility depends on engine design, with belt-in-oil systems demanding precise sealing and oil circulation, whereas conventional belts fit engines with exposed belt drives and standard maintenance intervals.

Pros and Cons: Belt-in-Oil vs Conventional Timing Belts

Belt-in-oil timing belts offer enhanced durability and reduced friction as they operate submerged in engine oil, resulting in quieter performance and extended service intervals compared to conventional timing belts. Conventional timing belts are simpler to inspect and replace, often with lower upfront costs and easier maintenance in typical engine environments. However, belt-in-oil systems require specialized seals and precise oil management, increasing complexity and potential repair costs if leaks occur, while conventional belts are more prone to wear and may need more frequent replacement due to exposure to external conditions.

caratoz.com

caratoz.com