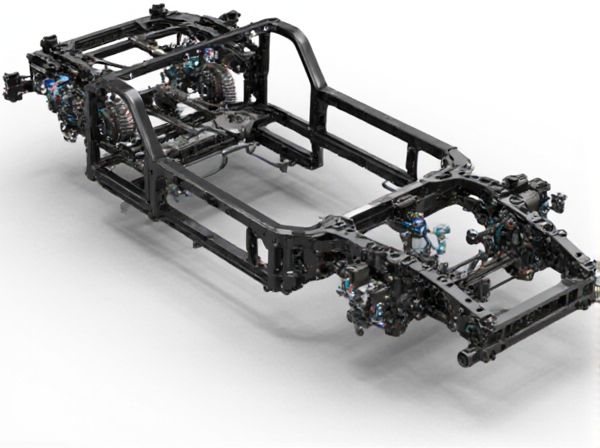

Photo illustration: Open Channel Frame vs Closed Box Frame

Open channel frames feature a U-shaped cross-section that offers easier access for maintenance and wiring, while closed box frames provide enhanced strength and rigidity due to their fully enclosed design. You should consider open channel frames for applications requiring frequent adjustments or installations, whereas closed box frames are ideal for heavy-duty uses where maximum structural support and protection from environmental factors are essential. Selecting the right frame depends on balancing your needs for accessibility, durability, and load-bearing capacity.

Table of Comparison

| Feature | Open Channel Frame | Closed Box Frame |

|---|---|---|

| Structure | U-shaped steel channels, open on one side | Rectangular or square hollow steel sections fully enclosed |

| Weight | Lighter due to less material usage | Heavier but offers enhanced rigidity |

| Strength & Rigidity | Lower torsional stiffness, prone to twisting | High torsional rigidity, resists deformation |

| Manufacturing Complexity | Simple and cost-effective fabrication | Complex welding and fabrication, higher cost |

| Durability | More susceptible to corrosion due to open sections | Improved durability, protected internal surfaces |

| Applications | Used in economy cars, light-duty vehicles | Common in performance, luxury, and heavy-duty vehicles |

Introduction to Frame Structures

Open channel frames feature a U-shaped cross-section, offering lightweight construction and ease of access for maintenance, commonly used in conveyor systems and light machinery supports. Closed box frames consist of hollow rectangular or square sections, providing superior torsional rigidity and strength, ideal for heavy-duty applications like automotive chassis and structural beams. Both frame types are fundamental in structural engineering, selected based on load requirements and stability considerations.

Definition of Open Channel Frame

An Open Channel Frame is a structural design featuring exposed channels that allow easy access for maintenance, ventilation, and weight reduction. This frame type contrasts with a Closed Box Frame, which encloses the structure, offering increased rigidity and protection against environmental factors. Open Channel Frames are commonly used in applications where flexibility and cooling are prioritized over maximum strength.

Overview of Closed Box Frame

Closed box frames offer superior torsional rigidity compared to open channel frames, making them ideal for heavy-duty applications and improved structural stability. Their design encloses the frame on all sides, providing enhanced resistance to twisting and bending forces. This construction results in higher load-bearing capacity and durability, commonly utilized in automotive chassis and industrial machinery.

Key Structural Differences

Open channel frames feature a U-shaped cross-section that offers easier access for maintenance and wiring while providing moderate torsional rigidity. Closed box frames consist of fully enclosed rectangular or square tubing, delivering superior torsional strength and resistance to twisting under load, making them ideal for heavy-duty applications. The choice between them depends on the balance between accessibility, weight, and structural stiffness required for the specific engineering project.

Load-Bearing Capabilities

Open channel frames exhibit moderate load-bearing capabilities due to their U-shaped cross-section, which provides good resistance to bending but less torsional rigidity. Closed box frames offer superior strength and stiffness with their enclosed rectangular or square profiles, effectively distributing loads and minimizing deformation under high stress. Engineering analyses demonstrate that closed box frames are preferable in applications demanding enhanced structural integrity and durability.

Applications and Use Cases

Open channel frames are widely used in applications requiring easy access for maintenance, inspection, and installation, such as in electrical equipment racks, cooling systems, and lightweight structural supports. Closed box frames provide enhanced strength, rigidity, and protection from environmental factors, making them ideal for heavy machinery, automotive chassis, and outdoor equipment housing. Industries like manufacturing, automotive, and telecommunications choose open channel frames for flexibility and closed box frames for durability and load-bearing capacity.

Advantages of Open Channel Frames

Open Channel Frames provide superior flexibility and ease of access for maintenance and installation compared to Closed Box Frames, facilitating quicker adjustments and inspections. Their open design improves ventilation, reducing heat buildup and enhancing equipment longevity in industrial applications. Cost-effectiveness and reduced weight make Open Channel Frames a preferred choice for structures requiring efficient load support without excessive material use.

Benefits of Closed Box Frames

Closed box frames provide superior torsional rigidity compared to open channel frames, enhancing vehicle stability and handling performance. The enclosed structure offers increased resistance to twisting forces, which is critical for off-road and heavy-duty applications. Enhanced durability and load distribution make closed box frames ideal for supporting higher payloads and extending chassis lifespan.

Cost Considerations

Open Channel Frames typically incur lower initial costs due to simpler design and reduced material usage compared to Closed Box Frames, which require more steel and fabrication time. Maintenance expenses for Open Channel Frames tend to be higher as they offer less protection against corrosion and environmental damage, necessitating more frequent inspections and repairs. Closed Box Frames provide better durability and longevity, potentially reducing lifecycle costs despite their higher upfront investment.

Choosing the Right Frame for Your Project

Selecting the right frame for your project depends on factors such as load capacity, environmental conditions, and structural requirements. Open channel frames offer ease of access and ventilation, making them suitable for applications requiring frequent inspection or cooling, while closed box frames provide superior strength, rigidity, and protection against contaminants, ideal for heavy-duty or harsh environments. Evaluating the specific needs of your project ensures optimal performance, durability, and maintenance efficiency.

caratoz.com

caratoz.com