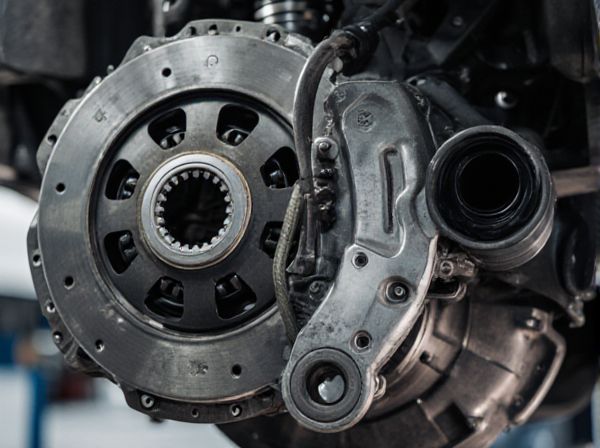

Photo illustration: Clutch plate vs Cone clutch

A clutch plate provides direct contact friction for smooth power transmission in vehicles, while a cone clutch uses a conical surface to increase frictional grip, offering higher torque capacity in a compact design. You benefit from the clutch plate's simplicity in maintenance and consistent engagement, whereas the cone clutch excels in applications requiring greater force without slipping. Understanding these differences helps in selecting the right clutch type for performance and durability.

Table of Comparison

| Feature | Clutch Plate | Cone Clutch |

|---|---|---|

| Design | Flat, circular friction plate | Conical friction surfaces |

| Friction Surface Area | Smaller, contact on flat surfaces | Larger, tapered surface contact |

| Torque Transmission | Moderate torque transfer | High torque capacity due to wedging action |

| Wear Rate | Higher wear, frequent maintenance | Lower wear, durable over time |

| Engagement Smoothness | Smooth clutch engagement | More abrupt engagement |

| Application | Common in manual car transmissions | Used in heavy vehicles and racing cars |

| Complexity & Cost | Simple and cost-effective | More complex and expensive |

Introduction to Clutch Plate and Cone Clutch

A clutch plate, commonly used in automotive transmissions, consists of friction material bonded to a steel disk that engages and disengages power between the engine and the drivetrain. A cone clutch operates through a conical friction surface, providing a larger contact area and smoother torque transfer compared to flat clutch plates. Both clutch types play crucial roles in controlling torque transmission but differ significantly in design, application, and performance characteristics.

Basic Working Principle

A clutch plate operates by pressing a friction disc between the flywheel and pressure plate to engage and disengage power transmission in a vehicle. In contrast, a cone clutch functions by fitting a conical friction surface into a matching cone, engaging torque through axial force along the cones' contact area. Both systems rely on frictional force to transmit torque, but the cone clutch provides a larger frictional surface area, allowing smoother engagement under higher loads compared to the flat friction surface of a clutch plate.

Design and Construction Differences

Clutch plates feature flat friction surfaces made from materials like organic compounds or Kevlar, designed for smooth engagement and efficient power transmission in automotive systems. Cone clutches utilize a conical friction surface, creating a wedging effect that increases torque capacity through axial force, commonly found in heavy machinery and racing applications. The design difference lies in the contact area and friction mechanics: clutch plates rely on parallel surfaces while cone clutches use angled surfaces to enhance grip and load handling.

Materials Used in Clutch Plate vs Cone Clutch

Clutch plates are typically made from composite materials combining friction linings such as asbestos-free organic compounds, ceramics, or Kevlar on a steel or aluminum backing to withstand high friction and heat. Cone clutches generally use metallic friction surfaces made of hardened steel or cast iron, often combined with brass or bronze facings to provide smooth engagement and wear resistance. The choice of materials in clutch plates emphasizes thermal stability and friction durability, while cone clutches prioritize metal-to-metal contact for reliable torque transfer and longevity.

Performance and Efficiency Comparison

Clutch plates offer higher torque capacity and smoother engagement, making them ideal for high-performance vehicles requiring precise control and durability under varied load conditions. Cone clutches provide better torque transmission efficiency through increased friction surface area, enabling quicker power transfer with less slippage but may wear faster under heavy use. Overall, clutch plates excel in longevity and consistent performance, while cone clutches maximize immediate efficiency in compact applications.

Durability and Maintenance Requirements

Clutch plates typically offer higher durability due to their ability to withstand greater friction and heat, making them suitable for heavy-duty applications. Cone clutches require frequent maintenance because their conical contact surfaces are prone to wear and require precise alignment to maintain performance. The simpler design and robust materials of clutch plates result in lower maintenance costs compared to the more delicate, wear-sensitive cone clutch mechanisms.

Applications in Modern Vehicles

Clutch plates are predominantly used in modern manual transmission vehicles due to their efficient torque transfer and smooth engagement under varying load conditions. Cone clutches find limited application in some heavy-duty and racing vehicles where high torque capacity and compact design are critical, but they are less common in everyday passenger cars. The widespread adoption of clutch plates in standard automotive systems reflects their reliability and ease of maintenance compared to the more specialized cone clutch configurations.

Advantages of Clutch Plate System

The clutch plate system offers superior heat dissipation compared to cone clutches, resulting in enhanced durability and consistent performance under high torque conditions. It provides smoother engagement and disengagement, reducing wear and tear on transmission components. Maintenance is simpler due to standardized parts and easier access, making it a preferred choice in modern automotive applications.

Benefits of Cone Clutch Mechanism

Cone clutch offers superior torque transmission due to its larger contact surface area, reducing slippage compared to a clutch plate. Its self-energizing effect minimizes the required input force, enhancing efficiency and durability in heavy-duty applications. The cone clutch design also ensures smoother engagement and better heat dissipation, prolonging the lifespan of the clutch components.

Which Clutch Type is Best for Your Needs?

Choosing between a clutch plate and a cone clutch depends on your mechanical requirements and application specifics. Clutch plates offer better heat dissipation and smoother engagement, ideal for high-speed vehicles or machinery requiring frequent gear shifts. Cone clutches provide higher torque capacity and compact design, making them suitable for heavy-duty applications where space is limited and strong holding power is essential.

caratoz.com

caratoz.com