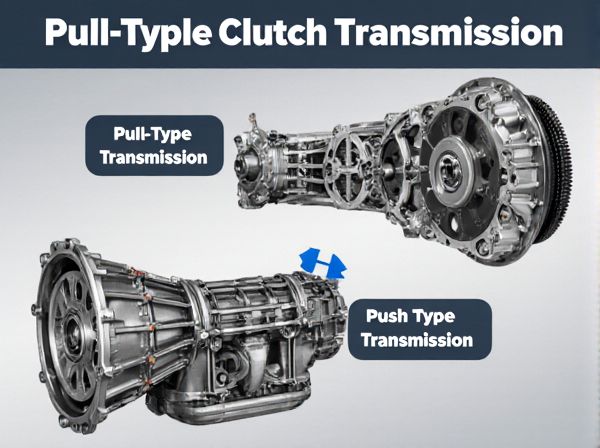

Photo illustration: Pull-type Clutch Transmission vs Push-type Clutch Transmission

Pull-type clutch transmissions engage by pulling the clutch disc away from the flywheel, offering smoother pedal feel and precise control, which enhances driving comfort and performance. Push-type clutch transmissions operate by pushing the clutch disc toward the flywheel, typically providing a simpler design but potentially stiffer pedal action and less modulation. Understanding these differences helps you choose the best clutch type for your vehicle's driving characteristics and maintenance preferences.

Table of Comparison

| Feature | Pull-type Clutch Transmission | Push-type Clutch Transmission |

|---|---|---|

| Operating Mechanism | Engages by pulling the clutch fork | Engages by pushing the clutch fork |

| Pedal Effort | Generally lighter pedal effort | Typically higher pedal effort |

| Clutch Fork Design | Uses a fork that pulls the pressure plate | Uses a fork that pushes the pressure plate |

| Installation Complexity | More complex linkage setup | Simpler, more direct linkage |

| Common Use | Often found in performance cars | Widely used in everyday passenger vehicles |

| Maintenance | Easier cable adjustment and maintenance | Requires periodic hydraulic system checks |

| Durability | Durable under high-stress conditions | Reliable with regular servicing |

| Response Time | Faster clutch engagement response | Smoother but slightly delayed engagement |

Introduction to Clutch Transmission Systems

Clutch transmission systems are crucial for controlling power transfer between an engine and a vehicle's drivetrain, optimizing performance and efficiency. Pull-type clutch transmissions engage by pulling the release mechanism, resulting in quicker response times and smoother disengagement under load. Push-type clutch transmissions operate by pushing the release bearing, offering simpler design and easier maintenance but potentially slower engagement compared to pull-type systems.

Defining Pull-type and Push-type Clutches

Pull-type clutch transmissions engage by pulling the clutch release mechanism, typically using a cable or hydraulic system that applies force to disengage the clutch. Push-type clutch transmissions operate by pushing the release mechanism to separate the clutch plates, often relying on a direct mechanical linkage or hydraulic actuator. The primary distinction lies in the direction of force applied to control the clutch engagement, influencing the design and maintenance requirements of the transmission system.

How Pull-type Clutch Transmissions Work

Pull-type clutch transmissions operate by engaging the clutch mechanism through a pulling action on the control cable or rod, which retracts the pressure plate away from the clutch disc, allowing the engine to disengage from the transmission smoothly. This design typically results in more precise control and quicker response due to the direct tension applied in the clutch release system. The pull-type mechanism is favored in applications requiring minimal pedal effort and reliable clutch engagement, enhancing overall vehicle drivability and transmission longevity.

How Push-type Clutch Transmissions Work

Push-type clutch transmissions operate by applying force directly to the clutch release bearing through a fork or hydraulic system, which pushes the clutch pressure plate away from the clutch disc to disengage power from the engine to the transmission. The linear motion generated by the clutch pedal or hydraulic actuator moves the release bearing forward, compressing the diaphragm spring and creating separation between the clutch components. This mechanism offers precise pedal feel and is commonly used in modern vehicles for smoother gear shifting and reduced pedal effort.

Key Differences Between Pull-type and Push-type Clutch Transmissions

Pull-type clutch transmissions engage the clutch by pulling the release bearing away from the pressure plate, resulting in a lighter pedal feel and reduced effort for the driver. Push-type clutch transmissions operate by pushing the release bearing toward the pressure plate, often providing a more direct engagement but requiring greater pedal force. Key differences include the direction of clutch engagement force, variations in pedal effort, and the mechanical design considerations affecting maintenance and durability.

Advantages of Pull-type Clutch Transmission

Pull-type clutch transmissions offer enhanced durability by reducing the risk of increased leverage wear on the clutch release bearing, resulting in longer service life. They provide smoother engagement and improved control due to the consistent cable tension during clutch operation. Maintenance is simplified as the pull-type mechanism allows easier cable adjustment and less frequent replacement compared to push-type systems.

Benefits of Push-type Clutch Transmission

Push-type clutch transmissions offer enhanced durability by reducing the load on release bearings, leading to longer component lifespan. Improved pedal feel and lighter clutch operation contribute to increased driver comfort and control, benefiting both daily driving and performance applications. This design also simplifies maintenance due to easier access and fewer complex parts, resulting in lower service costs over time.

Common Applications in Automotive Engineering

Pull-type clutch transmissions are commonly used in motorcycles and small vehicles, where lighter weight and simpler mechanism enhance performance and maintenance. Push-type clutch transmissions dominate in larger automotive applications such as trucks and passenger cars due to their robust design and better heat dissipation under high torque conditions. Both types are critical in optimizing vehicle drivability and efficiency, with selection heavily influenced by engine power, vehicle size, and intended use.

Performance and Durability Comparison

Pull-type clutch transmissions typically offer smoother engagement and reduced pedal effort, enhancing overall driving comfort and performance. Push-type clutch transmissions generally provide greater durability and higher torque capacity due to their simpler design and more robust components. Performance-wise, pull-type systems excel in precision and responsiveness, while push-type systems are favored for long-term reliability and heavy-duty applications.

Choosing the Right Clutch Transmission for Your Vehicle

Choosing the right clutch transmission between pull-type and push-type depends on your vehicle's design and performance needs. Pull-type clutches offer easier engagement and are ideal for lightweight vehicles, while push-type clutches provide better durability and are preferred in heavy-duty applications. Assess factors such as vehicle weight, driving conditions, and maintenance preferences to select the most compatible clutch transmission system for optimal performance and longevity.

caratoz.com

caratoz.com