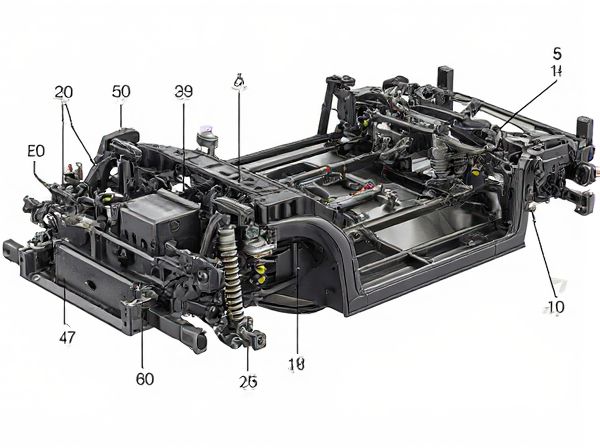

Photo illustration: Torsion Box vs Perimeter Frame

Torsion box construction offers superior rigidity and strength by creating a hollow core panel that resists twisting and warping, making it ideal for large table tops and work surfaces. Perimeter frame construction relies on a solid frame around the edges, providing stability but less resistance to torsional forces compared to a torsion box. Choosing between the two depends on your need for durability, weight considerations, and the specific application of the furniture or structure.

Table of Comparison

| Chassis Type | Torsion Box | Perimeter Frame |

|---|---|---|

| Structure | Box-shaped, closed section providing high torsional rigidity | Open frame surrounding the perimeter of the vehicle |

| Torsional Strength | High torsional stiffness, reduces flexing during cornering | Moderate torsional resistance with some flex under stress |

| Weight | Generally lighter due to efficient material distribution | Heavier because of additional frame components |

| Manufacturing Complexity | More complex welding and assembly process | Simpler design, easier to manufacture |

| Cost | Higher production cost linked to complexity | Lower manufacturing cost |

| Application | Common in sports cars and vehicles requiring high rigidity | Used in trucks and SUVs prioritizing durability |

Introduction to Torsion Box and Perimeter Frame

A torsion box is a lightweight, rigid structure commonly used in furniture and cabinetry, featuring a grid of internal supports enclosed by thin panels to resist twisting forces. A perimeter frame consists of a solid outer frame that provides strength and stability by distributing loads along its edges, often used in door and window construction. Both methods enhance structural integrity but differ in weight distribution and material usage.

Understanding the Torsion Box Structure

The torsion box structure consists of a rigid frame with a lightweight core, typically made from honeycomb or grid materials, sandwiched between two thin face sheets to resist twisting forces effectively. Its design enhances stiffness and strength while minimizing weight, making it ideal for applications requiring durability and rigidity, such as furniture tops and aerospace components. Compared to perimeter frames, torsion boxes distribute stress across the entire surface, reducing deformation under load and improving long-term performance.

What is a Perimeter Frame?

A perimeter frame is a structural woodworking technique where the frame outlines the edges of a panel, providing support and stability by transferring loads around its perimeter. This method contrasts with torsion box construction, which uses an internal grid of cells for rigidity. Perimeter frames are commonly used in furniture and cabinetry to enhance durability and allow for panel movement without warping.

Strength and Stability Comparison

Torsion box designs offer superior strength and stability due to their internal grid structure, which distributes loads evenly and resists twisting forces more effectively than perimeter frames. Perimeter frame constructions rely primarily on outer edges for rigidity, making them more susceptible to warping and flexing under stress. For applications demanding high load-bearing capacity and minimal deformation, torsion boxes provide enhanced structural integrity and longevity.

Weight Differences and Material Efficiency

Torsion box construction offers superior weight reduction by using a hollow core structure that maximizes material efficiency, resulting in lighter panels compared to perimeter frame designs that rely on solid edges. The torsion box's internal grid pattern distributes loads evenly while using less material, which decreases overall weight without compromising strength. Perimeter frame designs often require heavier solid framing to maintain rigidity, making them less efficient in terms of material usage and weight optimization.

Cost Considerations and Budget Impact

Torsion box construction typically involves higher material and labor costs due to its complexity and need for precise assembly, impacting budgets more significantly than perimeter frame designs. Perimeter frame structures offer a cost-effective alternative by using fewer materials and simpler construction methods, making them suitable for budget-conscious projects. Evaluating project size, required strength, and finish quality helps determine which framing method provides the best balance between cost savings and structural performance.

Applications and Best Use Cases

Torsion box construction excels in applications requiring lightweight yet rigid panels, such as cabinet doors, furniture tops, and workbench surfaces, providing superior resistance to warping and twisting. Perimeter frame designs are best suited for structural framing in doors, windows, and larger furniture pieces where strength at the edges is critical to support load and maintain shape. Selecting torsion box or perimeter frame depends on factors like load distribution, panel size, and the need for dimensional stability in specific woodworking or architectural projects.

Ease of Construction and Assembly

Torsion box construction offers straightforward assembly through its rigid internal grid, which minimizes material warping and simplifies alignment during build. Perimeter frame designs require more precise joinery skills to ensure frame stability, often complicating the construction process. The integrated structure of torsion boxes reduces assembly time by combining support and surface into one cohesive unit.

Durability and Long-Term Performance

Torsion box construction offers enhanced durability due to its internal web structure distributing stress evenly, reducing warping and sagging over time. Perimeter frame designs rely on solid outer edges for support, which can be prone to weaker centers and potential deformation under heavy loads. Long-term performance favors torsion boxes in applications requiring consistent structural integrity and resistance to environmental changes.

Which to Choose: Torsion Box or Perimeter Frame?

Choosing between a torsion box and a perimeter frame depends on the intended application and load requirements. Torsion boxes offer superior rigidity and resistance to twisting, making them ideal for heavy-duty workbenches and tables requiring enhanced stability, while perimeter frames provide sufficient support for lighter tasks and simpler construction. Evaluating weight distribution, material costs, and assembly complexity helps determine the optimal choice for durability and performance.

caratoz.com

caratoz.com