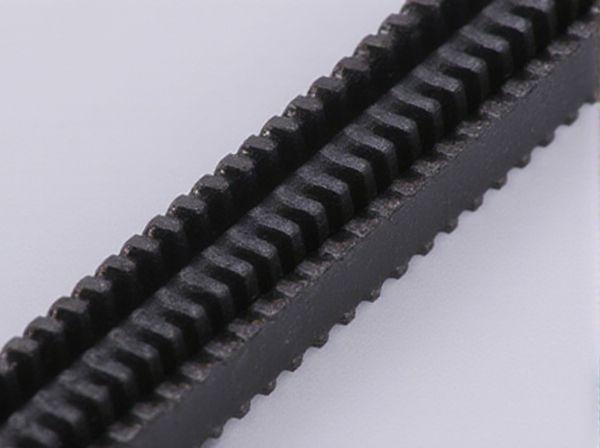

Photo illustration: Fluoroelastomer-Coated Timing Belt vs Standard-Coated Timing Belt

Fluoroelastomer-coated timing belts offer superior resistance to heat, chemicals, and oils compared to standard-coated timing belts, making them ideal for demanding industrial applications. Your machinery benefits from enhanced durability and longer service life when using fluoroelastomer coatings, reducing maintenance costs and downtime. Standard-coated belts provide adequate performance for general-purpose use but may degrade faster under harsh conditions.

Table of Comparison

| Feature | Fluoroelastomer-Coated Timing Belt | Standard-Coated Timing Belt |

|---|---|---|

| Durability | High resistance to heat, chemicals, and wear | Moderate, less resistant to harsh conditions |

| Temperature Range | -20degC to 200degC (-4degF to 392degF) | -10degC to 120degC (14degF to 248degF) |

| Chemical Resistance | Excellent against oils, solvents, and fuels | Limited chemical resistance |

| Lifespan | Up to 150,000 miles or 7 years | Up to 60,000 miles or 4 years |

| Cost | Higher initial cost | Lower initial cost |

| Application | High-performance and demanding engine environments | Standard engines with normal operating conditions |

Introduction to Timing Belt Coatings

Fluoroelastomer-coated timing belts offer superior chemical resistance and high-temperature performance compared to standard-coated timing belts, which typically use rubber or polyurethane coatings. The fluoroelastomer coating enhances belt durability in harsh environments, ensuring longer service life and improved reliability in automotive and industrial applications. Standard coatings provide adequate performance for general use but may degrade faster under exposure to oils, chemicals, or extreme temperatures.

Overview of Fluoroelastomer-Coated Timing Belts

Fluoroelastomer-coated timing belts feature superior chemical resistance and high-temperature stability compared to standard-coated timing belts, making them ideal for harsh environments in automotive and industrial applications. These belts offer enhanced durability against oils, fuels, and solvents while maintaining optimal flexibility and tensile strength. Their specialized fluoropolymer coating contributes to reduced wear and extended service life under extreme operational conditions.

Standard-Coated Timing Belts Explained

Standard-coated timing belts feature a durable fabric cover typically made from materials like nylon or polyester, providing essential protection against abrasion and environmental factors. These belts maintain high tensile strength with embedded fiberglass or Kevlar cords, ensuring reliable power transmission in automotive and industrial applications. Compared to fluoroelastomer-coated belts, standard-coated timing belts offer cost-effective performance with sufficient resistance to heat and oil but may have limited chemical and temperature resistance.

Key Material Differences

Fluoroelastomer-coated timing belts utilize a specialized fluoroelastomer polymer that provides superior chemical resistance, heat stability up to 200degC, and enhanced durability against oils and solvents compared to standard-coated belts, which typically use polyurethane or rubber coatings. The fluoroelastomer's molecular structure offers exceptional wear resistance and low friction properties, extending belt life in high-performance and harsh environments. Standard-coated timing belts may degrade faster under extreme temperatures and exposure to chemicals, making fluoroelastomer coatings preferable for automotive, aerospace, and industrial applications demanding reliability and longevity.

Durability and Wear Resistance Comparison

Fluoroelastomer-coated timing belts exhibit superior durability and wear resistance compared to standard-coated timing belts, thanks to their enhanced chemical stability and resistance to high temperatures. These belts maintain performance integrity under harsh conditions, reducing material degradation and extending operational lifespan. Standard-coated belts typically show faster wear rates when exposed to oils, chemicals, and elevated temperatures, leading to more frequent replacements.

Chemical and Temperature Resistance

Fluoroelastomer-coated timing belts exhibit superior chemical resistance, effectively withstanding exposure to oils, fuels, and solvents that typically degrade standard-coated belts. Their exceptional thermal stability allows continuous operation in temperatures ranging from -20degC to 200degC, surpassing the temperature limits of standard coatings which generally degrade above 80degC to 120degC. This enhanced chemical and temperature resistance makes fluoroelastomer-coated belts ideal for demanding industrial and automotive applications requiring durability and reliability under harsh conditions.

Performance under Stress and Load

Fluoroelastomer-coated timing belts exhibit superior resistance to high temperatures, chemicals, and wear compared to standard-coated timing belts, resulting in enhanced durability under extreme stress and heavy load conditions. These belts maintain dimensional stability and exhibit less elongation, ensuring precise timing and reduced risk of belt slippage during peak performance demands. Standard-coated timing belts tend to degrade faster under intense operational environments, limiting their effectiveness in high-stress applications.

Cost Considerations and Value

Fluoroelastomer-coated timing belts generally incur higher upfront costs compared to standard-coated timing belts due to advanced material properties like enhanced chemical resistance and temperature tolerance. Despite the premium price, fluoroelastomer coatings extend belt lifespan and reduce maintenance frequency, delivering superior long-term value in demanding industrial environments. Evaluating total cost of ownership, including downtime and replacement expenses, often reveals fluoroelastomer belts as a more economical choice over standard-coated alternatives.

Applications and Industry Suitability

Fluoroelastomer-coated timing belts offer enhanced chemical resistance, high-temperature tolerance up to 200degC, and superior durability, making them ideal for automotive, aerospace, and chemical processing industries. Standard-coated timing belts, typically made with polyurethane or rubber coatings, suit general mechanical applications with moderate temperature and chemical exposure such as packaging and printing machinery. Industries requiring precision and longevity in harsh environments benefit significantly from the specialized properties of fluoroelastomer coatings.

Which Timing Belt Coating Is Right for You?

Fluoroelastomer-coated timing belts offer superior chemical resistance, high-temperature endurance up to 200degC, and enhanced durability in harsh environments compared to standard-coated belts, which are typically suited for general applications with moderate heat and wear. Choosing the right timing belt coating depends on your operational conditions: if exposure to oil, solvents, or extreme temperatures is frequent, fluoroelastomer coatings provide optimal performance and longevity. For routine mechanical setups without aggressive chemical exposure, standard-coated timing belts remain a cost-effective and reliable choice.

caratoz.com

caratoz.com